Apr 25,2024

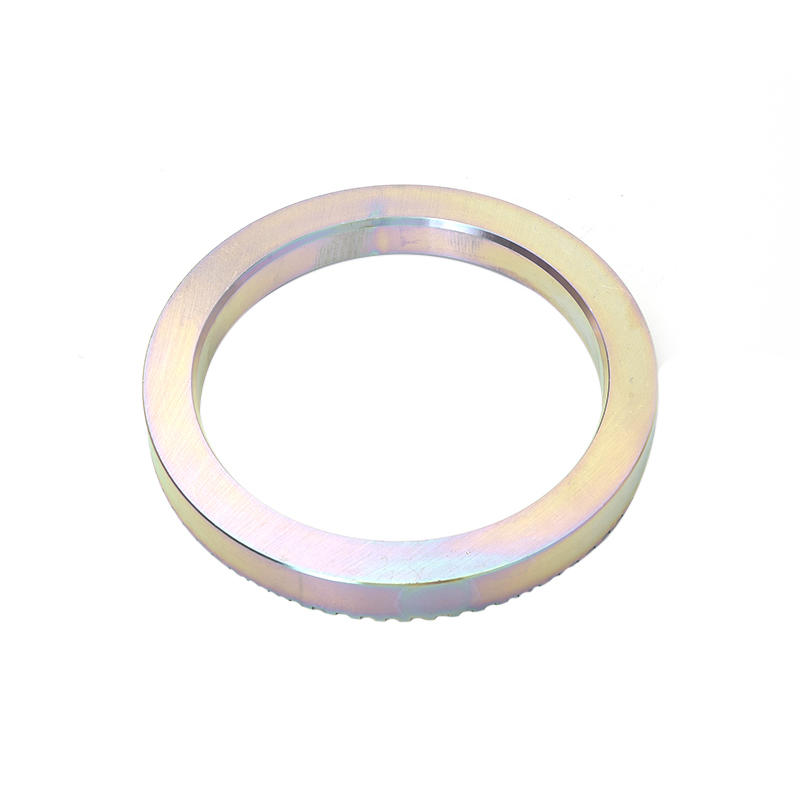

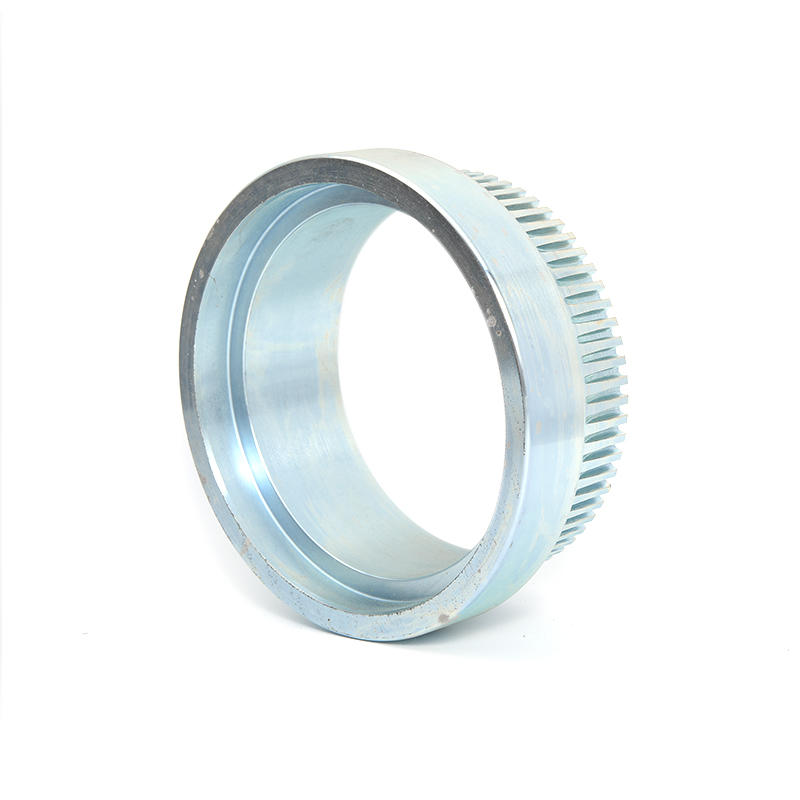

The surface finish of an axle sleeve for an automobile ball cage plays a crucial role in its functionality and performance. The axle sleeve, also known as a bearing race, is the part of the assembly that provides a smooth surface for the ball bearings to roll against. Here's how surface finish impacts the functionality of the axle sleeve:

Reduced Friction: A smooth surface finish on the axle sleeve reduces friction between the ball bearings and the raceway. This minimizes resistance to rotation, allowing the bearings to move freely and efficiently, which is essential for smooth operation and optimal performance of the bearing assembly.

Wear Resistance: A high-quality surface finish enhances the wear resistance of the axle sleeve, prolonging its lifespan and ensuring long-term durability of the bearing assembly. The smooth surface reduces abrasive wear on the ball bearings and helps prevent premature failure due to surface damage or roughness.

Sealing Effectiveness: The surface finish of the axle sleeve can affect the effectiveness of seals or shields that protect the bearing assembly from contamination and moisture ingress. A smooth surface provides a better sealing surface, reducing the risk of leaks and ensuring reliable protection against environmental contaminants.

Load Distribution: The surface finish of the axle sleeve plays a role in distributing the load evenly across the bearing assembly. A smooth and uniform surface helps distribute the load more effectively, reducing localized stress concentrations and minimizing the risk of fatigue failure or premature wear in specific areas.

Noise and Vibration Reduction: A smooth surface finish on the axle sleeve contributes to noise and vibration reduction in the bearing assembly. By minimizing surface irregularities and imperfections, the smooth surface reduces noise generation and vibration levels, resulting in quieter and smoother operation of the automotive component.

Compatibility with Lubrication: The surface finish of the axle sleeve affects its compatibility with lubricants used in the bearing assembly. A smooth surface promotes proper lubricant distribution and retention, enhancing the effectiveness of lubrication in reducing friction, dissipating heat, and protecting against wear and corrosion.

Overall, the surface finish of the axle sleeve for an automobile ball cage directly influences its functionality, performance, and longevity. A smooth and high-quality surface finish is essential for reducing friction, enhancing wear resistance, improving sealing effectiveness, distributing loads evenly, reducing noise and vibration, and ensuring compatibility with lubrication. These factors are critical for achieving reliable and efficient operation of automotive bearing assemblies.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com