Nov 30,2024

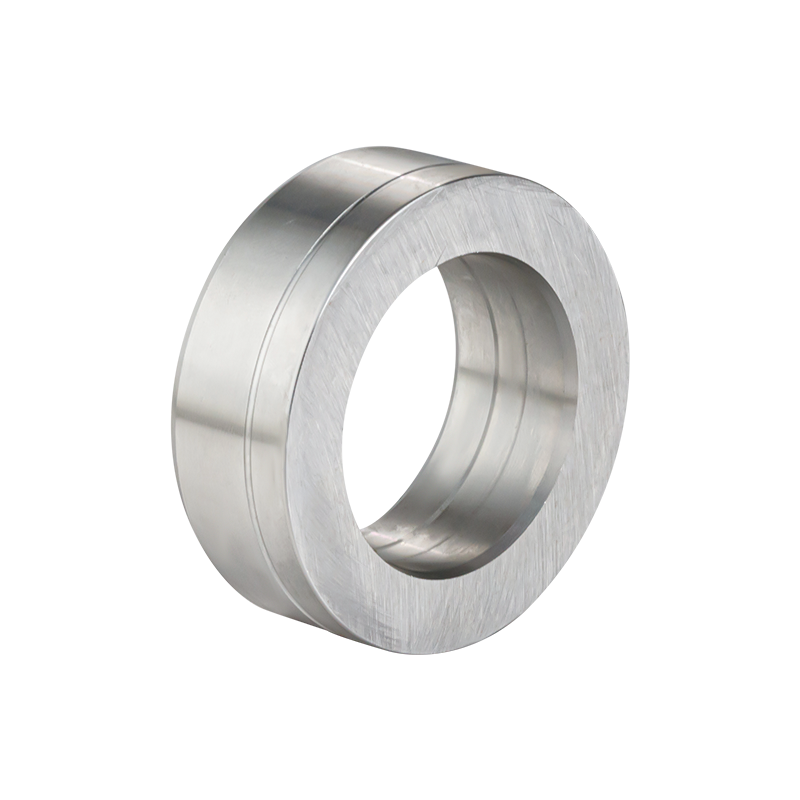

Axle sleeves for automobile ball cages, also known as axle bushings or axle bearings, are critical components that provide support and reduce friction in the suspension system. The materials used in manufacturing axle sleeves are chosen based on their durability, wear resistance, and ability to withstand the harsh conditions encountered in automotive applications. Common materials include:

Bronze:

Bronze is a popular material for axle sleeves due to its excellent wear resistance, self-lubricating properties, and ability to withstand heavy loads. Phosphor bronze and aluminum bronze are commonly used alloys in this application.

Steel:

Steel axle sleeves are known for their strength and durability. Alloy steels, such as 4140 or 4340, are often used to provide high tensile strength and resistance to wear. Steel sleeves may be coated or treated for additional corrosion resistance.

Aluminum:

Aluminum axle sleeves are chosen for their lightweight properties and corrosion resistance. They are often used in applications where weight reduction is a priority. Aluminum alloys, such as 6061 or 7075, may be used for their strength and durability.

Polymer Composites:

Some modern axle sleeves incorporate polymer composites, such as reinforced plastics or thermoplastic materials. These composites offer benefits like low friction, resistance to corrosion, and reduced weight. Examples include polyamide, polyoxymethylene (POM), or other high-performance polymers.

Brass:

Brass axle sleeves are used for their corrosion resistance and relatively good machinability. They are often alloyed with other materials to enhance specific properties.

Bearing Bronze:

Bearing bronze, which typically contains a higher percentage of tin, is chosen for its excellent wear resistance and compatibility with lubricants. This material is well-suited for high-load applications.

Sintered Metals:

Sintered metal axle sleeves are manufactured by compacting and sintering metal powders. This process can produce porous structures that can be impregnated with lubricating oils or other additives, enhancing self-lubricating properties.

Stainless Steel:

Stainless steel axle sleeves are chosen for their corrosion resistance in harsh environments. Grades such as 304 or 316 stainless steel may be used to provide durability and resistance to corrosion.

The specific material selected for axle sleeves depends on factors such as the application, load requirements, environmental conditions, and the desired balance between strength, wear resistance, and other properties. In many cases, a combination of materials, such as a metal sleeve with a polymer or self-lubricating liner, may be used to optimize performance.

It's essential for axle sleeve materials to withstand the dynamic forces, vibrations, and temperature variations experienced in automotive suspension systems. Additionally, proper lubrication and maintenance practices contribute to the longevity and performance of axle sleeves in ball cages and other suspension components.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com