Nov 30,2024

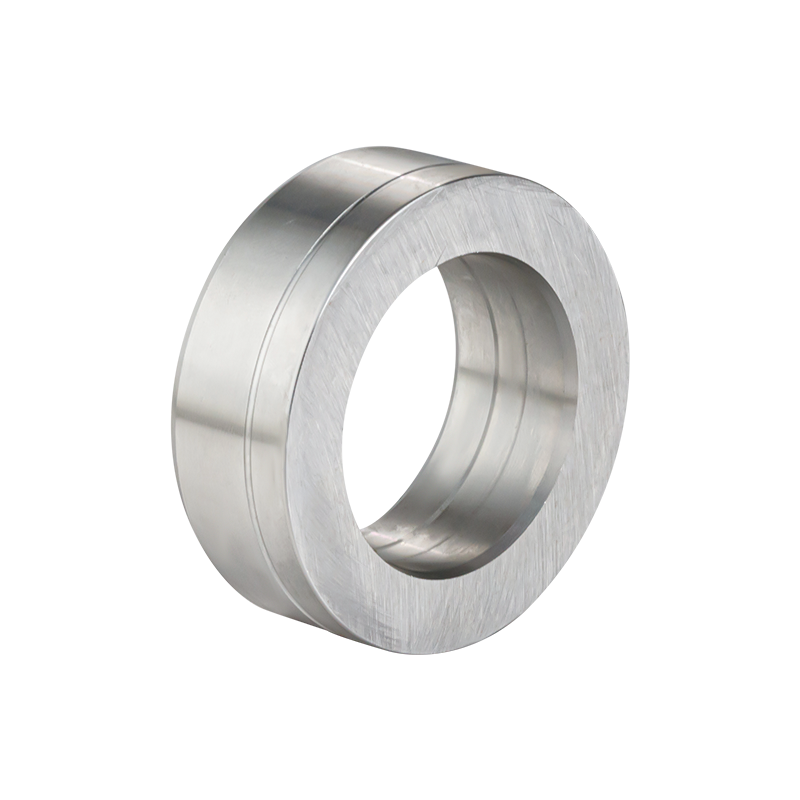

The purpose of an axle sleeve in an automobile context is to provide support, reduce friction, and maintain proper alignment within the axle system. Axle sleeves play a critical role in ensuring the efficient and reliable operation of the axle assembly. Here are the main purposes of axle sleeves:

Support and Structural Integrity: Axle sleeves are often used to support and reinforce the axle components, particularly in areas where stress and load concentrations occur. They add strength to the axle system, preventing deformation or failure under heavy loads or harsh conditions.

Reducing Friction: Axle sleeves help reduce friction between moving parts within the axle assembly. By providing a smooth surface for contact between components like bearings, hubs, and spindles, axle sleeves contribute to efficient rotation and movement.

Alignment and Stability: Axle sleeves help maintain proper alignment between various axle components. They prevent components from shifting or moving out of position, which is crucial for ensuring stable and safe driving performance.

Wear Reduction: By acting as a barrier between metal surfaces, axle sleeves can help reduce wear and extend the lifespan of the axle components. This is particularly important in heavy-duty applications where components are subjected to frequent stress and friction.

Corrosion Resistance: Axle sleeves are often made from materials that offer corrosion resistance, such as stainless steel or other treated metals. This helps protect the axle assembly from rust and corrosion, enhancing its longevity and performance.

Heat Dissipation: In certain axle systems, axle sleeves may aid in heat dissipation by providing a pathway for heat to transfer away from high-friction areas. This can help prevent overheating and potential damage to components.

Preventing Galling: Galling is a form of adhesive wear that can occur when two metal surfaces rub against each other under pressure. Axle sleeves can help prevent galling by creating a smoother interface between components.

Load Distribution: Axle sleeves contribute to even load distribution across the axle assembly, preventing concentrated stress points that could lead to premature component failure.

Ease of Maintenance: Some axle sleeves are designed to be easily replaceable, allowing for simpler maintenance and repair of the axle system.

Overall, axle sleeves play a vital role in ensuring the integrity, longevity, and reliable performance of the axle assembly in automobiles. Their presence helps reduce wear, friction, and stress on critical components, contributing to safe and efficient operation on the road.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com