Jul 23,2024

The design of the bushing has a crucial impact on the overall safety and reliability of the automotive ball cage constant velocity joint assembly. This impact is not only reflected in the mechanical performance of the assembly, but also involves the overall safety performance of the vehicle and the passenger riding experience. Below, we will conduct an in-depth analysis of the impact of bushing design on automotive ball cage constant velocity universal joint assemblies from multiple aspects.

First of all, the design of the bushing is directly related to the assembly accuracy and stability of each component in the ball cage constant velocity universal joint assembly. An excellent bushing design can ensure that the fitting clearance between components is just right. It will neither cause looseness and wear due to excessive clearance, nor cause assembly difficulties or stress concentration due to too small clearance. Such a design can significantly reduce the failure rate caused by poor fit, thereby ensuring the overall reliability of the assembly.

Secondly, the material selection and processing technology of the bushing have a decisive impact on the safety and durability of the assembly. High-quality bushing materials need to have excellent strength and wear resistance and be able to withstand various complex stresses and frictions generated during driving. At the same time, a reasonable heat treatment process can further improve the hardness and toughness of the bushing, so that it can still maintain good performance during long-term use.

In addition, the sleeve design also needs to fully consider lubrication and heat dissipation issues. A good lubrication system can effectively reduce friction and wear and reduce heat generation; and an efficient heat dissipation design can dissipate the generated heat in time to avoid damage to the sleeve due to overheating. These factors are directly related to the safety and reliability of the automotive ball cage constant velocity joint assembly, so they need to be given full attention during the design process.

In addition to the mechanical performance considerations mentioned above, bushing design also needs to pay attention to ergonomics and comfort factors. By optimizing the shape and size of the shaft sleeve, the transmission of vibration and noise can be reduced and ride comfort improved; at the same time, reasonable shaft sleeve design can also reduce the risk of component damage or failure caused by improper operation or accidents, further ensuring Passenger safety.

In order to increase the credibility of the article, we can cite some relevant research data or experimental results. For example, you can mention the test results of some authoritative organizations on the material performance and processing technology of the bushing, or quote the data on the impact of bushing design on vehicle performance in some actual cases.

In summary, the design of the bushing has a profound impact on the overall safety and reliability of the automotive ball cage constant velocity joint assembly. During the design and manufacturing process, we need to fully consider factors such as the fitting accuracy of the shaft sleeve, material selection, processing technology, lubrication and heat dissipation, and ergonomic principles to ensure that the performance of the assembly reaches optimal status.

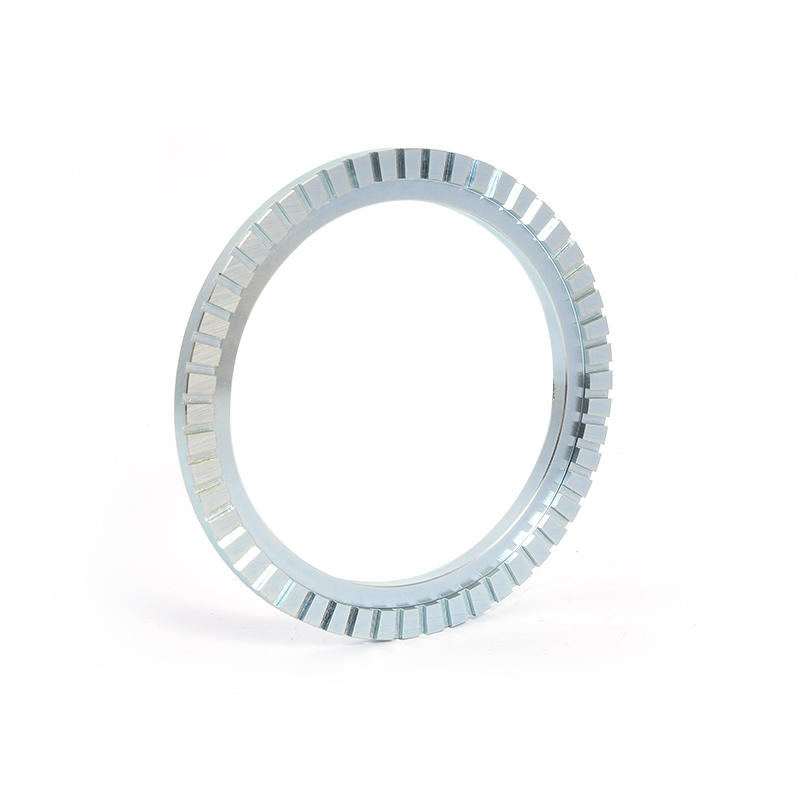

Axle Sleeve For Automobile Ball Cage

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com