Apr 25,2024

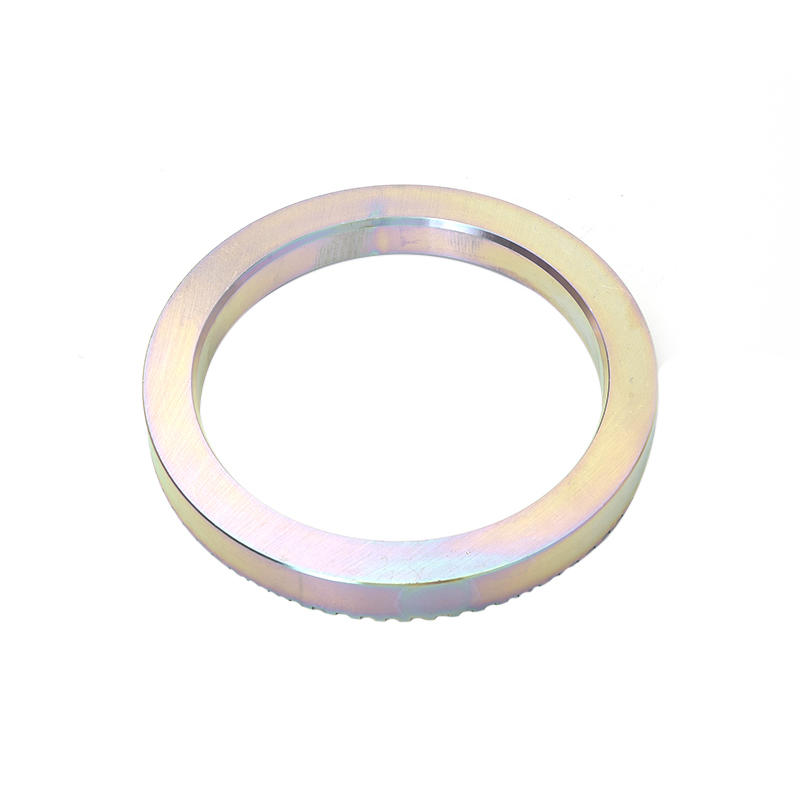

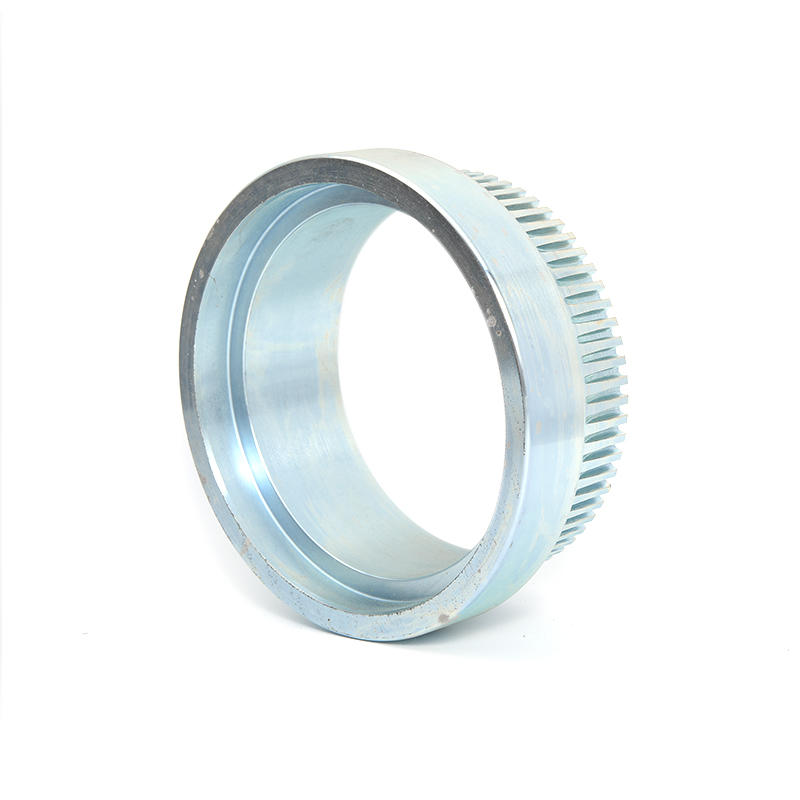

The selection of an axle sleeve for the automobile ball cage in vehicle manufacturing involves considering several factors to ensure optimal performance, durability, and safety. Here are some key factors that influence the selection of axle sleeves:

Material Compatibility:

The material of the axle sleeve should be compatible with the materials used in the ball cage and other surrounding components. Compatibility helps prevent corrosion, wear, and other material-related issues.

Load Capacity:

The axle sleeve must be capable of handling the specific load requirements of the vehicle. This includes the weight of the vehicle, cargo, and dynamic loads experienced during operation.

Wear Resistance:

The axle sleeve material should have good wear resistance to withstand the friction and abrasion encountered in the ball cage. This is particularly important for ensuring a long lifespan and minimal maintenance.

Heat Resistance:

The axle sleeve should be able to withstand the heat generated during normal vehicle operation. Heat resistance is crucial to prevent deformation or failure of the sleeve in high-temperature conditions.

Corrosion Resistance:

Resistance to corrosion is vital, especially in regions with harsh weather conditions or exposure to road salts. Corrosion-resistant axle sleeves contribute to the longevity of the ball cage and overall vehicle durability.

Dimensional Accuracy:

The axle sleeve must have precise dimensions to ensure a proper fit within the ball cage assembly. Dimensional accuracy is crucial for smooth operation and to prevent misalignment issues.

Manufacturing Process:

The manufacturing process of the axle sleeve can impact its quality and performance. Processes such as forging, casting, or machining may be used, and the chosen method should align with the required specifications and quality standards.

Cost Considerations:

Cost is a significant factor in the selection process. Manufacturers need to balance the performance requirements with the cost-effectiveness of the axle sleeve to ensure competitiveness in the market.

Weight Considerations:

Minimizing the weight of vehicle components is crucial for fuel efficiency and overall performance. Selecting lightweight yet strong materials for the axle sleeve contributes to the vehicle's weight optimization.

Friction and Lubrication:

Consideration of friction and lubrication characteristics is essential. The axle sleeve should be designed to work well with lubrication systems in place to minimize wear and ensure smooth operation.

Environmental Impact:

Some industries and consumers may prioritize environmentally friendly materials or processes. Considering the environmental impact of the materials used in the axle sleeve aligns with sustainability goals.

Regulatory Compliance:

Compliance with industry standards and regulations is crucial for ensuring the safety and reliability of the vehicle. The selected axle sleeve should meet or exceed relevant standards set by regulatory bodies.

By carefully evaluating these factors, automotive manufacturers can make informed decisions when selecting axle sleeves for the ball cage, contributing to the overall performance, safety, and reliability of the vehicle.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com