Nov 30,2024

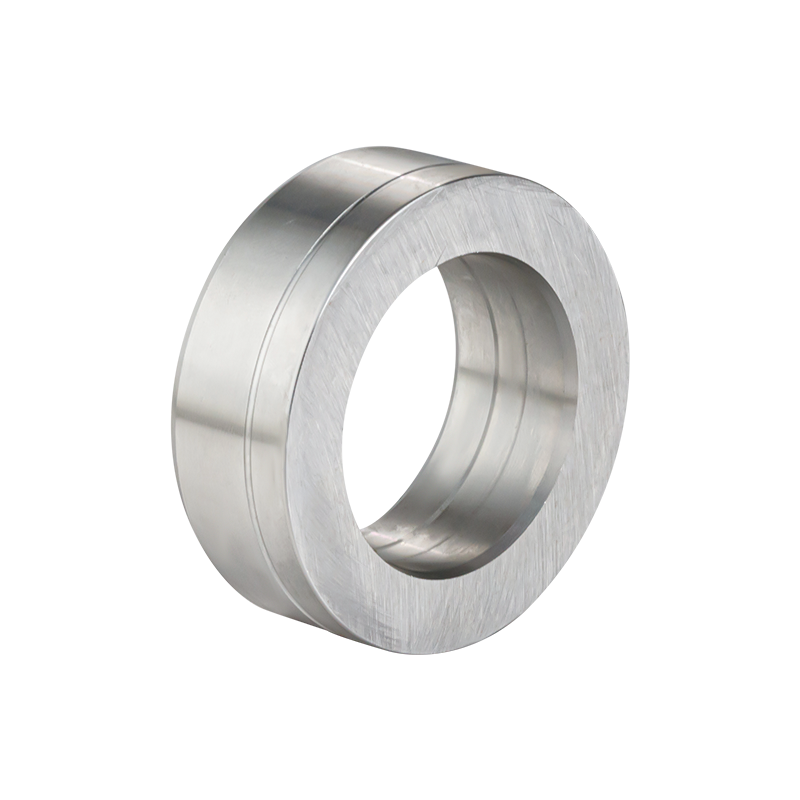

In mechanical engineering, bearings are key components that support rotating parts, reduce friction and transmit power. As one of the core parts of bearings, the material properties of Bearing Steel Sleeves directly determine its ability to withstand high loads.

Material property analysis

1. High carbon chromium bearing steel (GCr15/SUJ2)

The most commonly used material for Bearing Steel Sleeves is high carbon chromium bearing steel, such as GCr15 in international standards or SUJ2 in Japanese standards. This steel has the following significant characteristics:

High hardness and wear resistance: Through appropriate heat treatment processes, high carbon chromium bearing steel can obtain extremely high hardness, usually above HRC60. This high hardness enables Bearing Steel Sleeves to resist wear and maintain a long service life under high-speed rotation and heavy load conditions.

Good toughness: Despite its high hardness, high carbon chromium bearing steel also has good toughness and can absorb a certain amount of impact energy without breaking easily. This feature is essential to prevent damage caused by sudden loading or vibration.

Excellent fatigue resistance: Under cyclic loading conditions, high carbon chromium bearing steel exhibits excellent fatigue resistance. This means that it can maintain stable performance in long-term high-load operation and reduce cracks or failures caused by fatigue.

Good processing performance: The material is easy to cut, grind and heat-treat, making it easy to manufacture high-precision, low-roughness Bearing Steel Sleeves.

2. Other special materials

In addition to high carbon chromium bearing steel, with the advancement of technology and changes in industrial needs, some special materials Bearing Steel Sleeves have also been gradually developed and applied. For example:

Ceramic materials: have extremely high hardness and wear resistance, but the cost is high and suitable for extreme working conditions.

Stainless steel: has good corrosion resistance and is suitable for humid or corrosive environments.

Composite materials: combine the advantages of multiple materials, such as high hardness, low weight and excellent thermal stability, but the manufacturing process is complicated.

Why can it withstand high-load operation?

The reason why Bearing Steel Sleeves can withstand high-load operation is mainly due to its material characteristics and reasonable design:

Material strength: The high hardness and good toughness of high-quality materials such as high-carbon chromium bearing steel enable Bearing Steel Sleeves to withstand huge pressure and impact without being easily deformed or damaged.

Precision machining: Through precise machining processes such as high-precision grinding and heat treatment, the dimensional accuracy and surface roughness of Bearing Steel Sleeves can be ensured to reach an extremely high level, thereby reducing friction and wear and improving operating efficiency.

Lubrication system: An effective lubrication system can reduce friction and wear between Bearing Steel Sleeves and rotating parts, reduce temperature and prevent overheating. At the same time, the lubricant can also form a protective film between the contact surfaces, further improving its wear resistance.

Cooling system: Under high-speed and high-temperature operating conditions, a proper cooling system can ensure that the temperature of Bearing Steel Sleeves remains within a reasonable range to prevent performance degradation or damage caused by overheating.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com