May 16,2024

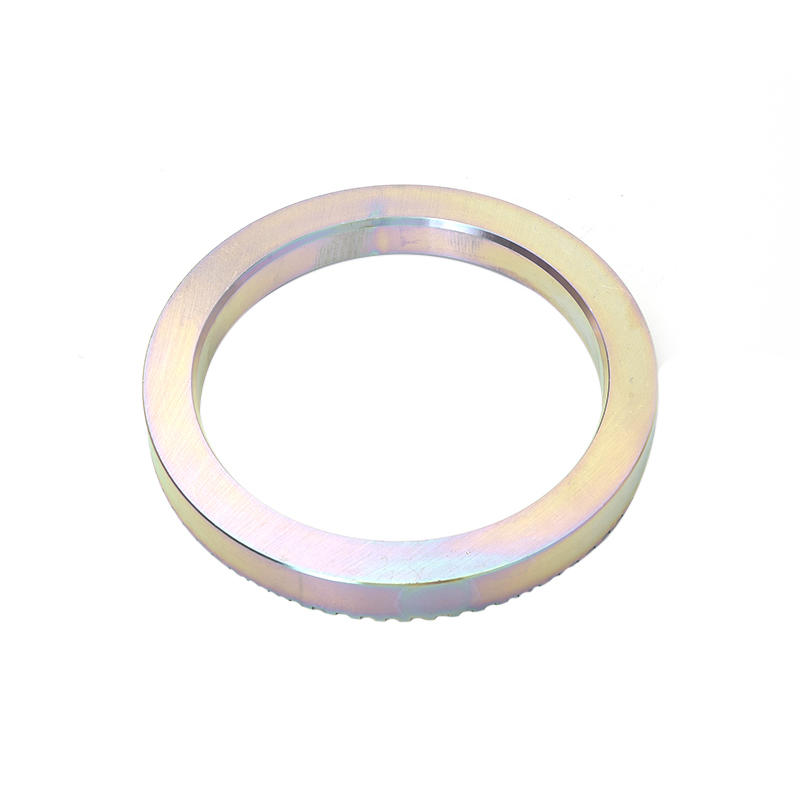

The manufacturing process of ABS Gear Ring Plane Gear involves several key processes and technical requirements to ensure high precision, high reliability and long life of the gear. The following are some key process and technical requirements during the manufacturing process:

Material selection and pre-processing:

Choose high-quality alloy steel with high strength, wear resistance and fatigue resistance as the gear material.

Heat treatment is performed on the material, such as normalizing, quenching and tempering, to improve the material's mechanical properties and wear resistance.

Investment casting or forging:

Precision casting or forging processes are used to ensure the basic shape and dimensional accuracy of the gear ring.

Controlling temperature, pressure, and cooling rates during casting or forging to reduce internal defects and residual stresses.

Machining:

High-precision CNC machine tools are used for rough machining, semi-finishing and finishing to ensure the accuracy of gear tooth shape, tooth pitch and tooth depth.

Strictly control cutting force, cutting speed and tool wear during processing to avoid work hardening and residual stress.

Heat treatment and surface treatment:

Carburizing, nitriding and other heat treatments are performed on the gears to improve tooth surface hardness and wear resistance.

Surface treatment technologies such as shot peening and polishing are used to improve the tooth surface roughness and improve the meshing performance of the gear.

Grinding and Grinding:

The gears are ground using high-precision grinders to ensure tooth profile accuracy and surface quality.

The gears are ground to further eliminate microscopic unevenness on the surface and improve the transmission efficiency of the gears.

Assembly and debugging:

During the assembly process, ensure the matching accuracy and installation position of the gear ring and other components.

Debugging the entire ABS system, checking the transmission performance and noise level of the gear ring to ensure that the design requirements are met.

Quality inspection and control:

During the manufacturing process, multiple process quality inspections are performed, such as dimensional measurement, hardness testing, metallographic analysis, etc.

Statistical process control (SPC) and other methods are used to monitor and adjust key process parameters to ensure stable and reliable product quality.

Through the strict implementation of the above key processes and technical requirements, high-quality ABS Gear Ring Plane Gear can be manufactured to provide a strong guarantee for the safe driving of the car.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com