Nov 30,2024

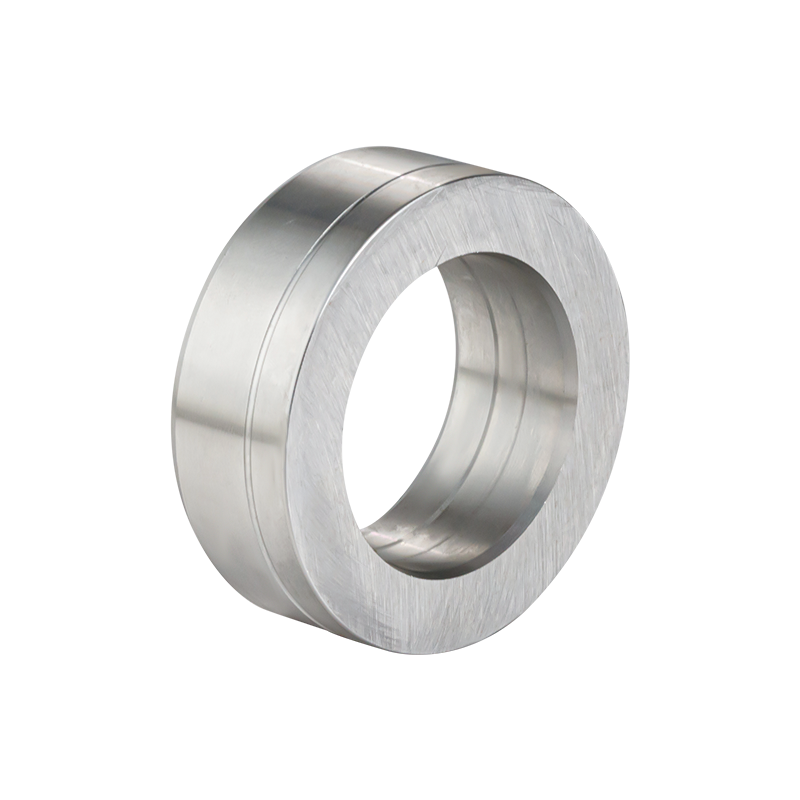

The manufacturing process of ABS Gear Ring Plane Gear has a significant key impact on its performance. The following are the specific impact aspects:

material selection:

The material selection of ABS Gear Ring Plane Gear directly affects its strength, wear resistance and corrosion resistance. For example, using high-strength, wear-resistant materials can significantly improve the life and performance of gear rings.

Heat treatment process:

Heat treatment processes such as quenching and tempering can improve the internal structure and performance of materials. Correct heat treatment can improve the hardness, toughness and wear resistance of the material, which plays an important role in the performance of the gear ring.

Molding:

The forming process of the gear ring, such as pressing, forging, casting, etc., will affect its internal structure and dimensional accuracy. For example, the optimization of the pressing process can ensure that the tooth density of the gear ring meets the drawing requirements, thereby improving its working performance.

Surface treatment technology:

Surface treatment technologies such as galvanizing and spraying can improve the surface quality of the gear ring and improve its corrosion resistance and wear resistance. As mentioned in reference article 1, the subsequent galvanized surface meets the drawing requirements, which is very important to improve the durability of the gear ring.

Dimensional accuracy:

The dimensional accuracy of the gear ring needs to be strictly controlled during the manufacturing process to ensure its matching accuracy with other components in the system. The improvement of dimensional accuracy can reduce friction and wear, and improve the transmission efficiency and service life of the gear ring.

QC:

Quality control measures in the manufacturing process such as quality inspection and random inspection can ensure the performance and quality of the gear ring. Through strict quality control, problems in the manufacturing process can be discovered and dealt with in time, ensuring that the performance of the gear ring meets the design requirements.

In summary, the manufacturing process of ABS Gear Ring Plane Gear has a significant key impact on its performance. By optimizing material selection, heat treatment process, molding process, surface treatment technology, and strengthening quality control, the performance and life of the gear ring can be significantly improved, thereby ensuring the stability and reliability of the ABS system.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com