Nov 30,2024

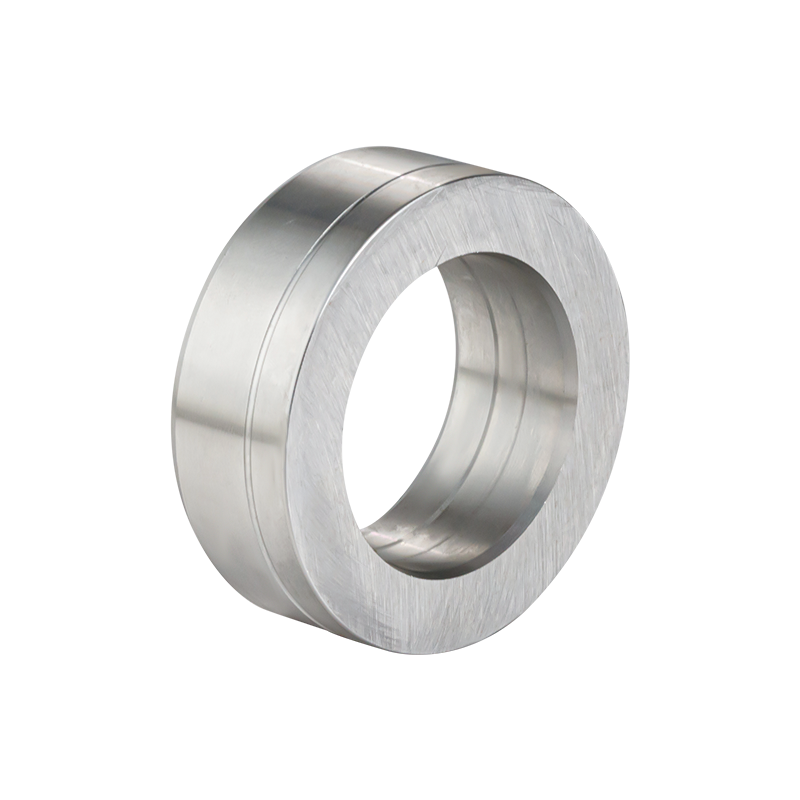

In the automotive industry, the Gear Ring Plane Gear of ABS (anti-lock braking system) is an important component to ensure vehicle driving safety. However, these gears are often accompanied by noise and vibration problems during operation, which not only affects driving comfort, but may also have an adverse effect on the performance and life of the system.

1. Lubrication optimization

A major source of noise and vibration is the friction between gears. By optimizing the lubrication system, this friction can be significantly reduced, thereby reducing noise and vibration. Specific methods include:

Use high-performance lubricants: Select lubricants with low friction coefficients and high wear resistance, which can effectively reduce friction and wear between gears, thereby reducing noise and vibration.

Regular lubrication maintenance: Establish a regular lubrication maintenance plan to ensure that the gear system is always properly lubricated to avoid noise and vibration caused by insufficient lubrication.

2. Shock and sound insulation design

Installing shock absorbers and sound insulation materials around the gear ring plane gear is an effective means to reduce noise and vibration transmission. Specific measures include:

Installation of shock-absorbing pads: Installing rubber shock-absorbing pads between gearboxes or related components can absorb and disperse vibration energy and reduce its transmission to the vehicle body and other components.

Using sound-absorbing materials: Wrapping the outside of the gearbox with sound-absorbing materials, such as sound-absorbing cotton or sound-insulating foam, can effectively isolate noise and reduce its transmission into the vehicle.

3. Structural optimization and reinforcement

By optimizing the structural design of the gear system and enhancing its rigidity and stability, the generation of vibration and noise can be fundamentally reduced. Specific measures include:

Enhancing the support structure: Strengthening the support structure of the gearbox, improving its vibration resistance, and reducing the noise caused by vibration.

Optimizing gear design: By optimizing the parameters such as the gear tooth shape, pitch, and meshing angle, the impact and vibration during the meshing process can be reduced, thereby reducing noise.

4. Precise assembly and calibration

Precise assembly and calibration are essential to reducing the noise and vibration of the gear system. Specific measures include:

High-precision assembly: During the assembly process, ensure that the meshing accuracy and axial and radial clearances of the gears meet the design requirements to avoid noise and vibration caused by assembly errors.

Dynamic balance adjustment: Dynamic balance detection and adjustment of key components to eliminate vibration caused by imbalance and ensure smooth operation of the system.

5. Intelligent control system

With the development of science and technology, intelligent control systems play an increasingly important role in vehicle noise and vibration control. For the ABS Gear Ring Plane Gear system, the following intelligent control technologies can be introduced:

Active noise control system: By equipping the active noise control system, the noise generated is automatically adjusted according to the vibration signal of the system to achieve active noise cancellation and reduce the discomfort of the driver and passengers.

Intelligent monitoring and feedback: Use intelligent sensors to monitor the noise and vibration levels of the gear system in real time, and use intelligent algorithms to perform multi-channel real-time control to quickly and accurately feedback and adjust the control strategy to ensure that the system is always in the best condition.

6. Innovative materials and processes

The use of new materials and advanced processes is also an important way to solve noise and vibration problems. For example:

Composite materials: Using composite materials with excellent shock absorption and sound insulation properties to manufacture gearboxes and related components can significantly improve the noise reduction effect of the system.

Precision machining technology: Use precision machining technology to improve the machining accuracy and surface quality of gears and reduce noise and vibration caused by machining errors.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com