Nov 30,2024

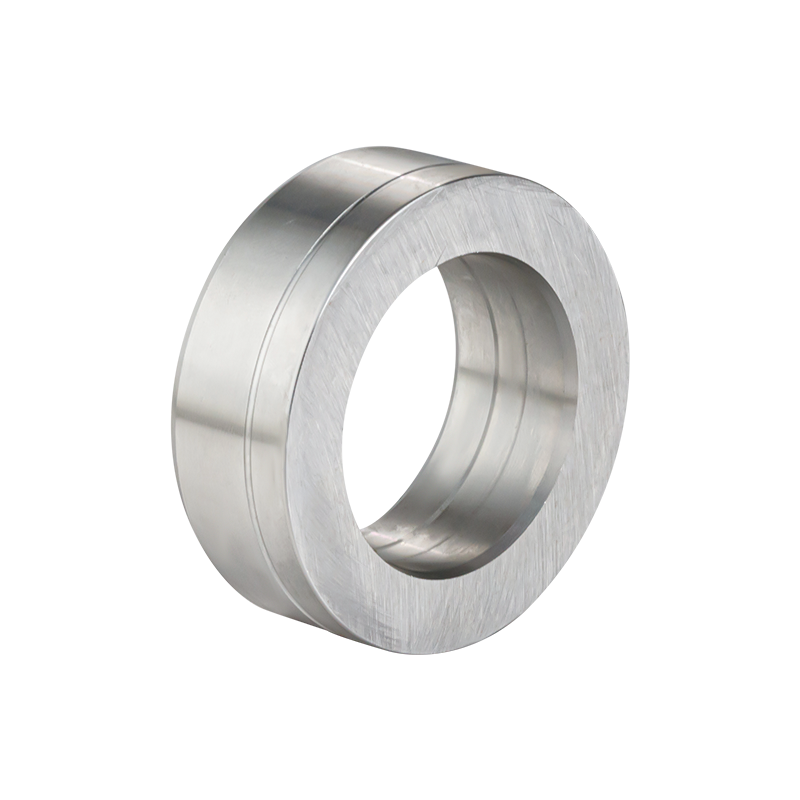

Axle sleeves, also known as axle shaft sleeves or axle bushings, play a crucial role in improving the performance and longevity of the automotive ball cage, which is a component found in constant velocity (CV) joints and axles of vehicles. Here's how axle sleeves contribute to enhancing automotive ball cage performance:

Reducing Friction and Wear: Axle sleeves are typically made of durable materials like bronze, steel, or composite materials with low friction coefficients. They serve as a bearing surface for the ball cage, reducing friction between moving parts. This reduction in friction helps to minimize wear and tear on the ball cage components, thereby extending its lifespan.

Supporting the Ball Bearings: Ball cages contain small ball bearings that allow for smooth and efficient rotation of the axle shaft. Axle sleeves provide structural support to these ball bearings and help maintain proper spacing and alignment between the balls. This ensures that the balls can roll smoothly within the cage, reducing friction and improving the efficiency of the joint.

Enhancing Load Distribution: Axle sleeves are designed to distribute the load evenly across the ball bearings within the cage. This even distribution of force helps prevent premature wear on specific areas of the ball cage, ensuring that it operates consistently and reliably under various driving conditions.

Reducing Vibration and Noise: The use of axle sleeves can help dampen vibrations and reduce noise generated during the operation of the CV joint. By providing a stable and well-supported environment for the ball bearings, axle sleeves contribute to quieter and smoother vehicle operation.

Improving Heat Dissipation: In high-stress situations, such as during rapid acceleration or heavy loads, automotive components can generate heat. Axle sleeves can act as heat sinks, absorbing and dissipating excess heat away from the ball cage and bearings. This helps prevent overheating and potential damage to the ball cage components.

Enhancing Durability: By reducing wear, minimizing friction, and improving load distribution, axle sleeves ultimately increase the durability and service life of the ball cage assembly. This is especially important in vehicles subjected to heavy-duty applications or off-road conditions.

Maintaining Lubrication: Axle sleeves can help retain lubrication within the CV joint by preventing contaminants from entering and lubricant from escaping. This ensures that the ball bearings remain well-lubricated, reducing the risk of corrosion and further extending the life of the ball cage.

In summary, axle sleeves are essential components that contribute to the smooth operation, longevity, and performance of automotive ball cages in CV joints and axles. Their role in reducing friction, supporting ball bearings, distributing loads, and enhancing overall durability is critical for maintaining the integrity of these components and ensuring the safe and reliable operation of the vehicle.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com