Nov 30,2024

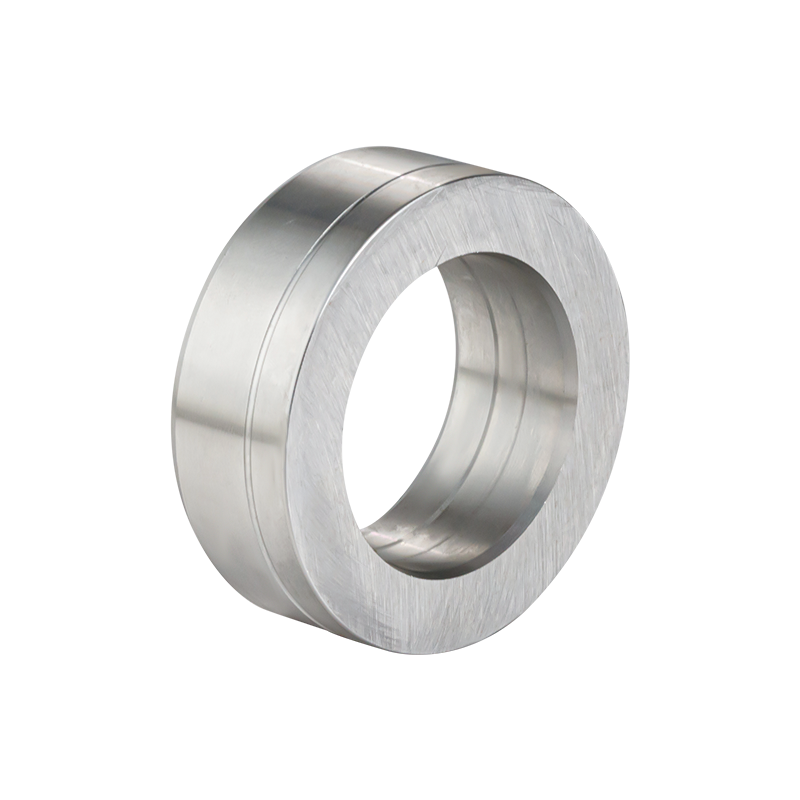

Axle sleeve design plays a crucial role in the efficiency and performance of automobile ball cages, particularly in various automotive components like constant velocity (CV) joints and universal joints. The axle sleeve, also known as the axle shaft or housing, provides support and guidance for the ball cage and bearings. Its design can impact several aspects of the automobile's functionality:

Load Bearing Capacity:

The design and material of the axle sleeve directly affect its load-bearing capacity. Robust axle sleeves are essential in CV joints and universal joints to withstand the forces transmitted through the drivetrain. Proper design ensures that the ball cage and bearings can handle the stresses without premature wear or failure.

Alignment and Precision:

Accurate alignment of the axle sleeve is critical to maintain proper positioning of the ball cage and bearings. Any misalignment can lead to increased friction, reduced efficiency, and premature wear. A well-designed axle sleeve ensures precise alignment, contributing to the smooth operation of the automobile.

Sealing and Lubrication:

The axle sleeve design should accommodate effective sealing mechanisms to prevent the ingress of contaminants and moisture. Proper sealing helps protect the ball cage and bearings from damage and ensures that lubrication remains effective for reducing friction.

Heat Dissipation:

In high-stress applications, such as heavy-duty trucks or performance vehicles, axle sleeves may need features for improved heat dissipation. Heat generated during operation can affect the lubrication and performance of the ball cage and bearings. Well-designed axle sleeves may incorporate cooling fins or other heat-dissipating features.

Material Selection:

The choice of material for the axle sleeve is critical. High-strength steel or alloys are commonly used to provide the required durability and load-bearing capacity. Material selection also affects the weight of the component, which can impact fuel efficiency and vehicle handling.

Reducing Weight:

In modern automotive design, there is an emphasis on reducing weight to improve fuel efficiency and vehicle performance. Lightweight axle sleeve materials or design modifications can help achieve this goal while maintaining strength and reliability.

Tolerance and Surface Finish:

The manufacturing precision of the axle sleeve, including tolerance and surface finish, affects the fit and function of the ball cage and bearings. Tight tolerances and a smooth surface finish are essential for minimizing friction and maximizing efficiency.

Durability and Longevity:

A well-designed axle sleeve contributes to the overall durability and longevity of the automobile's drivetrain components. It should be able to withstand years of use without excessive wear or failure.

Reducing Noise and Vibration:

Proper axle sleeve design can help reduce noise and vibration in the drivetrain. Vibration can lead to discomfort and can even affect the handling of the vehicle. Effective design can minimize these issues.

In summary, the design of the axle sleeve in an automobile's drivetrain components, such as CV joints and universal joints, directly impacts the efficiency, durability, and overall performance of the vehicle. Manufacturers pay careful attention to axle sleeve design to ensure that it meets the demanding requirements of modern automobiles, including load-bearing capacity, precision, sealing, heat dissipation, and longevity. These considerations are essential for maximizing the efficiency and reliability of the vehicle.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com