Nov 30,2024

As the automotive industry continues to evolve and adapt to changing demands, innovations in axle sleeve technology are playing a crucial role in enhancing the performance and durability of automobile ball cages. In this news article, we will delve into the latest advancements in axle sleeve technology, exploring how these innovations are positively impacting the automotive sector.

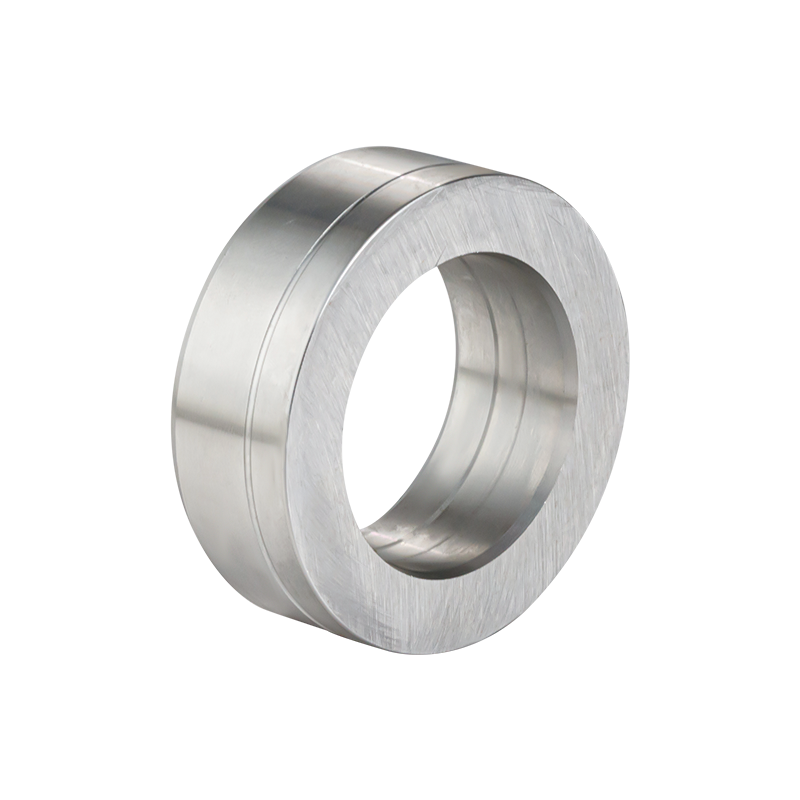

Axle sleeves are integral components within the automobile ball cage assembly, contributing to the smooth and efficient operation of a vehicle's wheels and suspension system. They play a vital role in reducing friction, enhancing load-bearing capacity, and ensuring that the ball bearings operate optimally, even under challenging conditions.

In recent years, engineers and manufacturers have been pushing the boundaries of axle sleeve design and materials, resulting in several noteworthy innovations:

1. Advanced Materials: The development of high-performance materials, such as heat-treated steels and advanced composites, has greatly improved the durability and longevity of axle sleeves. These materials offer superior resistance to wear, corrosion, and extreme temperatures, ensuring a longer service life.

2. Precision Manufacturing: Innovations in manufacturing processes, including precision machining and 3D printing, have enabled the creation of axle sleeves with intricate geometries and precise tolerances. This level of precision ensures a snug fit, minimizing play, and maximizing efficiency.

3. Lubrication Technologies: Novel lubrication solutions, such as self-lubricating axle sleeves, are gaining popularity for their ability to reduce maintenance requirements and extend the intervals between servicing. These innovations also contribute to quieter and smoother rides.

4. Weight Reduction: Automotive manufacturers are increasingly focusing on reducing vehicle weight to improve fuel efficiency. Innovations in lightweight materials and designs for axle sleeves play a pivotal role in achieving this goal without compromising strength and performance.

5. Noise and Vibration Control: Noise reduction has become a significant concern in the automotive industry. Innovations in axle sleeve technology include designs that dampen vibrations and reduce noise, leading to a more comfortable driving experience.

6. Sustainable Solutions: Eco-friendly materials and manufacturing processes are becoming a priority. Some innovations in axle sleeves involve the use of recyclable materials and environmentally conscious production methods.

The ongoing innovations in axle sleeve technology are not only enhancing the performance and reliability of automobile ball cages but also contributing to more sustainable and efficient vehicles. These advancements benefit both manufacturers and consumers, as they lead to reduced maintenance costs, increased vehicle longevity, and improved overall driving experiences.

In our upcoming articles, we will delve deeper into specific innovations and case studies that highlight the transformative impact of axle sleeve technology on the automotive industry. Stay tuned for more insights into this exciting and dynamic field of automotive engineering.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com