Nov 30,2024

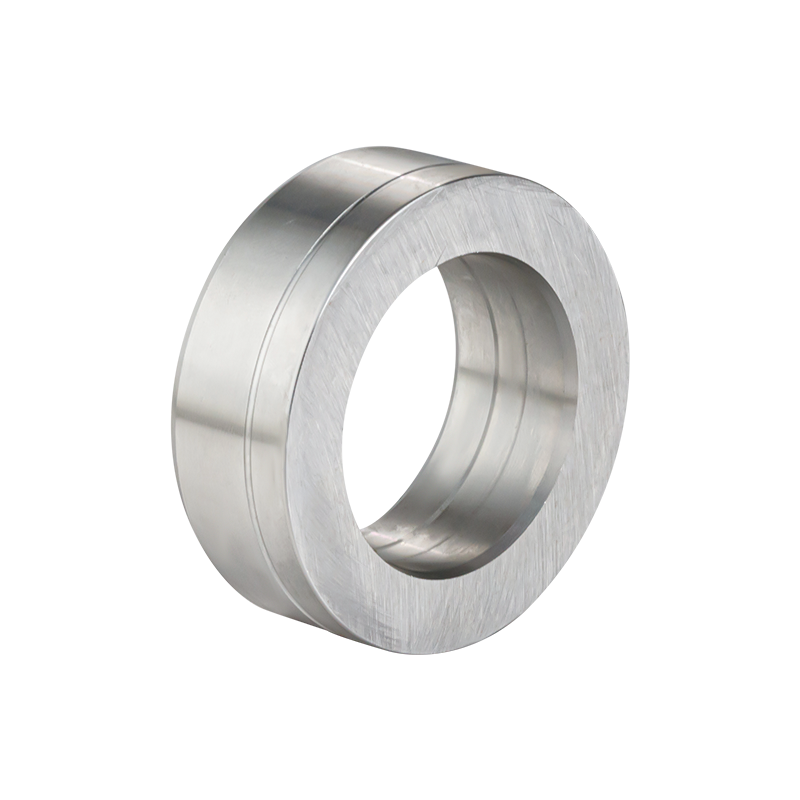

To solve the wear problem of ABS Gear Ring Plane Gear in long-term use, the following measures can be taken:

Optimize design and material selection:

Use high-strength and wear-resistant materials to manufacture ABS Gear Ring Plane Gear to improve its wear resistance.

Through optimized design, reduce stress concentration and uneven load distribution of gear ring plane gears during operation, thereby extending its service life.

Strengthen lubrication management:

Reasonably select lubricating oil and grease to ensure that the gear ring plane gear is fully lubricated during operation, reduce friction coefficient, and reduce wear.

Strictly carry out lubrication management according to lubrication cycle and quantity to ensure the cleanliness and effectiveness of lubricating oil, and avoid impurities and contaminants from causing wear to the gear ring plane gear.

Do a good job of maintenance:

Regularly inspect and maintain the ABS system, including checking the wear of the gear ring plane gear, and promptly discover and deal with wear problems.

In harsh working environments, the frequency of maintenance should be increased to ensure that the gear ring plane gear operates in good working condition.

Introduce advanced detection and diagnosis technology:

Use sensors and control systems to monitor the working status of the gear ring plane gear in real time, including parameters such as temperature, vibration, and noise, and detect abnormal conditions in time.

Introduce advanced fault diagnosis technologies, such as vibration analysis and oil analysis, to accurately diagnose the wear of the gear ring plane gear and provide a scientific basis for maintenance.

Improve the skill level of operators:

Strengthen the training and education of operators to improve their understanding and knowledge of the ABS system and its components.

Teach operators the correct operating methods and maintenance skills to reduce wear problems caused by improper operation.

Implement preventive maintenance strategies:

Develop a preventive maintenance plan and regularly replace or repair the ABS Gear Ring Plane Gear to prevent wear problems from accumulating to the point where they cannot be repaired.

Track and analyze the wear trend of the gear ring plane gear and adjust the preventive maintenance plan according to actual conditions.

Consider the impact of the use environment:

Analyze the use environment of the ABS system, such as the impact of factors such as temperature, humidity, and dust on the gear ring plane gear, and take corresponding protective measures.

For harsh use environments, special protective coatings or sealing measures can be considered to protect the gear ring plane gear.

Through the comprehensive application of the above measures, the wear problem of ABS Gear Ring Plane Gear in long-term use can be effectively solved, and the stability and reliability of the ABS system can be improved.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com