Nov 30,2024

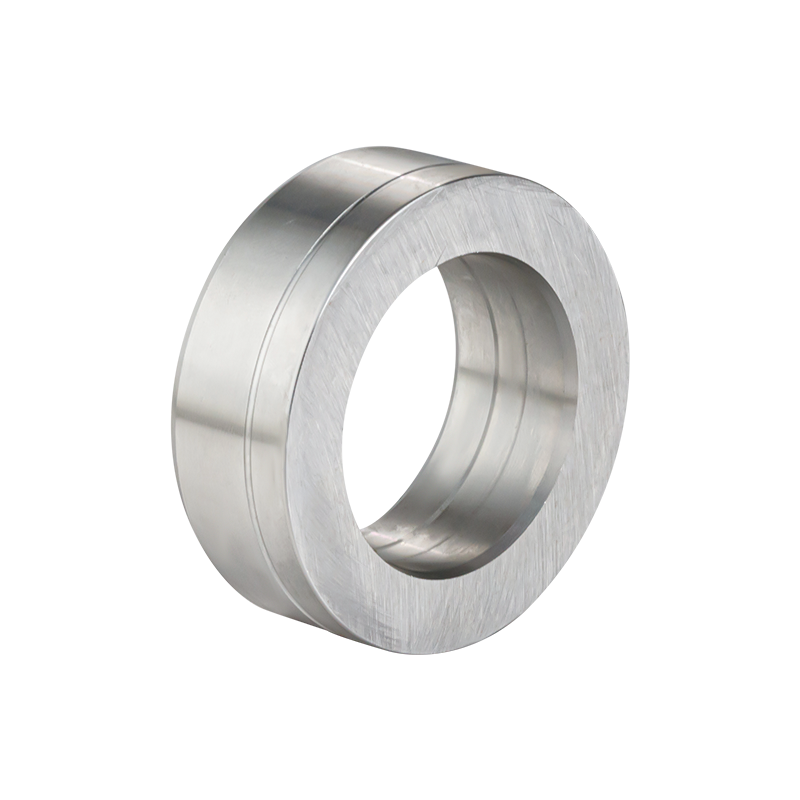

In the field of automobile manufacturing, every component plays a vital role, and Axle Sleeve For Automobile Ball Cage is an indispensable part. This seemingly insignificant component has a profound impact on the performance and durability of the car. Among them, the choice of material is one of the key factors.

Let's explore the impact of different materials on the durability of Axle Sleeve For Automobile Ball Cage. High-quality materials can withstand greater pressure, friction and impact, thereby extending the service life of the sleeve. For example, high-strength alloy steel has excellent hardness and toughness, and can maintain stable performance in harsh working environments. Sleeves made of this material can withstand greater axial and radial loads and reduce damage caused by overload. At the same time, alloy steel also has good wear resistance, which can resist friction with the ball cage and other components, reducing wear and loss.

In contrast, sleeves made of ordinary steel or cast iron may be slightly lacking in durability. The hardness and strength of these materials are relatively low, and they are prone to deformation, wear and even cracking during long-term use. In addition, their wear resistance is also poor, requiring more frequent maintenance and replacement, which increases the cost of using the car and the repair time.

In addition to durability, the material also has an important impact on the performance of the Axle Sleeve For Automobile Ball Cage. The right material can ensure the matching accuracy between the sleeve and the ball cage, improve the transmission efficiency and reduce energy loss. For example, the sleeve made of high-precision aluminum alloy has a light weight and good thermal conductivity. This can not only reduce the overall weight of the car and improve fuel economy, but also effectively dissipate the heat generated by friction, preventing the sleeve from overheating and affecting performance.

On the other hand, the choice of material will also affect the sealing performance of the sleeve. Some special rubber or plastic materials can be tightly combined with the sleeve to form a good seal, preventing dust, moisture and impurities from entering the interior of the ball cage, thereby protecting the ball cage and sleeve from corrosion and damage. Good sealing performance can also ensure the effective retention of lubricating oil, reduce friction and wear, and increase the service life of the sleeve.

In our company, we are well aware of the importance of materials for Axle Sleeve For Automobile Ball Cage. Therefore, we have been committed to selecting the best quality materials to produce our products. We use advanced material testing technology to ensure that each batch of materials meets strict quality standards. At the same time, we also work closely with domestic and foreign material suppliers to continuously explore and develop new materials to meet the needs of different customers.

Our Axle Sleeve For Automobile Ball Cage uses a variety of materials such as high-strength alloy steel and high-quality aluminum alloy. After careful design and strict processing, it has excellent durability and performance. Our products can not only maintain stable performance under various harsh road conditions, but also provide cars with more efficient transmission and better control experience.

The material of Axle Sleeve For Automobile Ball Cage has a vital impact on its durability and performance. Choosing high-quality materials can extend the service life of the sleeve and improve the performance and reliability of the car. Our company will continue to provide customers with high-quality Axle Sleeve For Automobile Ball Cage to escort your car.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com