Apr 25,2024

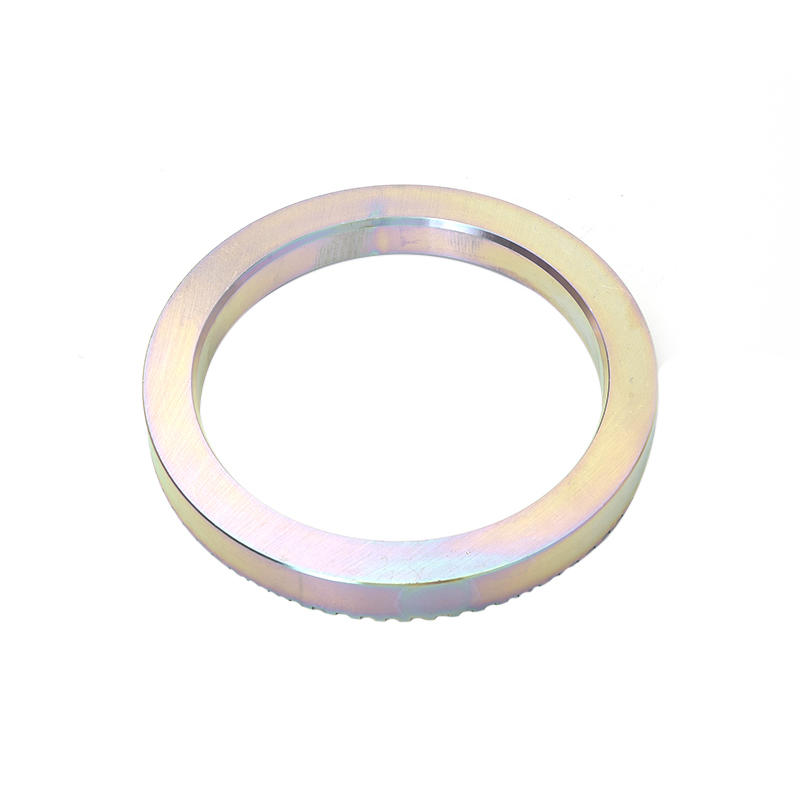

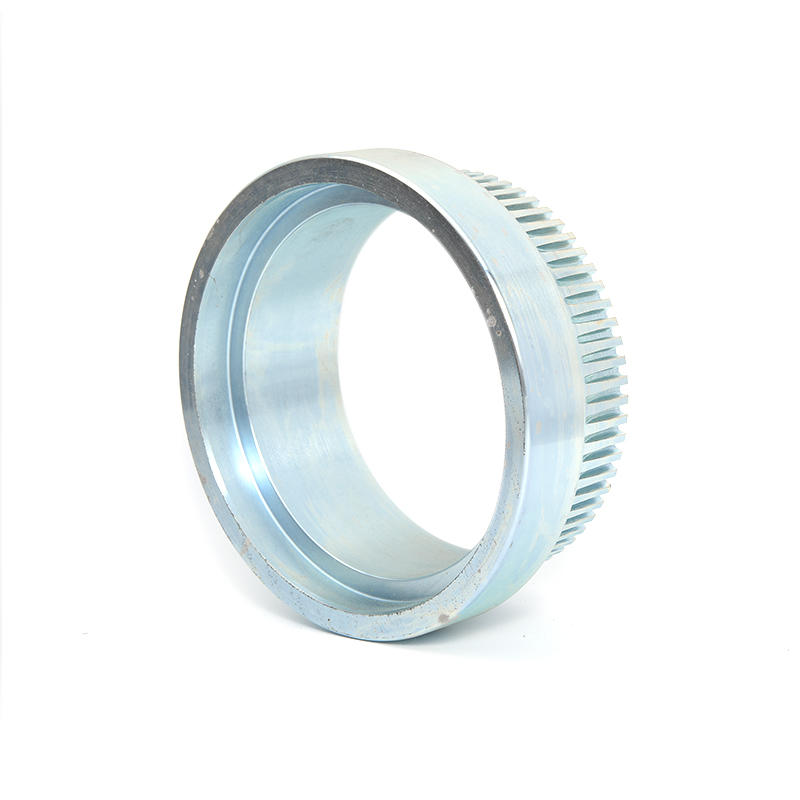

The material composition of the axle sleeve for an automobile ball cage plays a crucial role in determining its durability and overall performance. Here's an exploration of how the material composition influences the durability of the axle sleeve:

Wear Resistance:

Impact: The material's resistance to wear, abrasion, and friction is vital for prolonged durability.

Explanation: A high-quality material composition with wear-resistant properties ensures that the axle sleeve can withstand the constant movement and contact within the ball cage without significant degradation over time.

Corrosion Resistance:

Impact: The ability of the material to resist corrosion is critical for preventing deterioration due to exposure to environmental elements.

Explanation: Corrosion-resistant materials protect the axle sleeve from rust and degradation, contributing to its longevity and sustained performance even in challenging conditions.

Strength and Toughness:

Impact: The strength and toughness of the material affect the axle sleeve's ability to handle loads and stresses.

Explanation: A durable axle sleeve material should have sufficient strength to withstand the forces exerted during normal vehicle operation, ensuring it remains intact and reliable over an extended period.

Fatigue Resistance:

Impact: Materials with high fatigue resistance are crucial for components subjected to repetitive stress.

Explanation: The constant movement and loading in a ball cage system necessitate a material that can resist fatigue, preventing the development of cracks or fractures that could compromise the durability of the axle sleeve.

Temperature Stability:

Impact: The ability of the material to maintain its properties across a range of temperatures is essential for automotive applications.

Explanation: Variations in temperature, especially in the engine compartment, can impact material integrity. A stable material composition ensures consistent performance and durability under different temperature conditions.

Friction and Lubrication Compatibility:

Impact: The interaction with lubricants and the ability to reduce friction are critical for the durability of the axle sleeve.

Explanation: Proper material selection minimizes friction, reducing wear and tear on the axle sleeve. Compatibility with lubricants ensures effective lubrication, further enhancing durability.

Material Hardness:

Impact: The hardness of the material affects its resistance to deformation and surface damage.

Explanation: A balance in material hardness is essential to prevent excessive wear while maintaining the structural integrity of the axle sleeve, contributing to its overall durability.

Weight Considerations:

Impact: The weight of the material can influence the overall weight and efficiency of the ball cage system.

Explanation: Optimal material composition balances durability with weight considerations, contributing to the efficiency and fuel economy of the vehicle.

In summary, the material composition of the axle sleeve for an automobile ball cage significantly impacts its durability. A carefully selected material that addresses wear resistance, corrosion resistance, strength, fatigue resistance, temperature stability, friction and lubrication compatibility, material hardness, and weight considerations ensures a durable and reliable component that withstands the demands of automotive applications.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com