May 01,2024

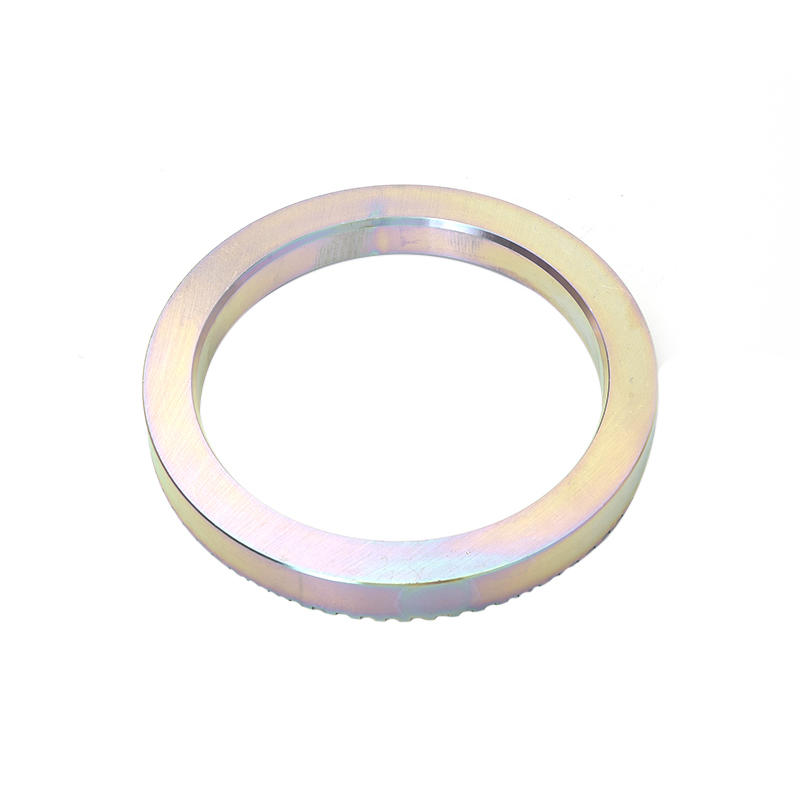

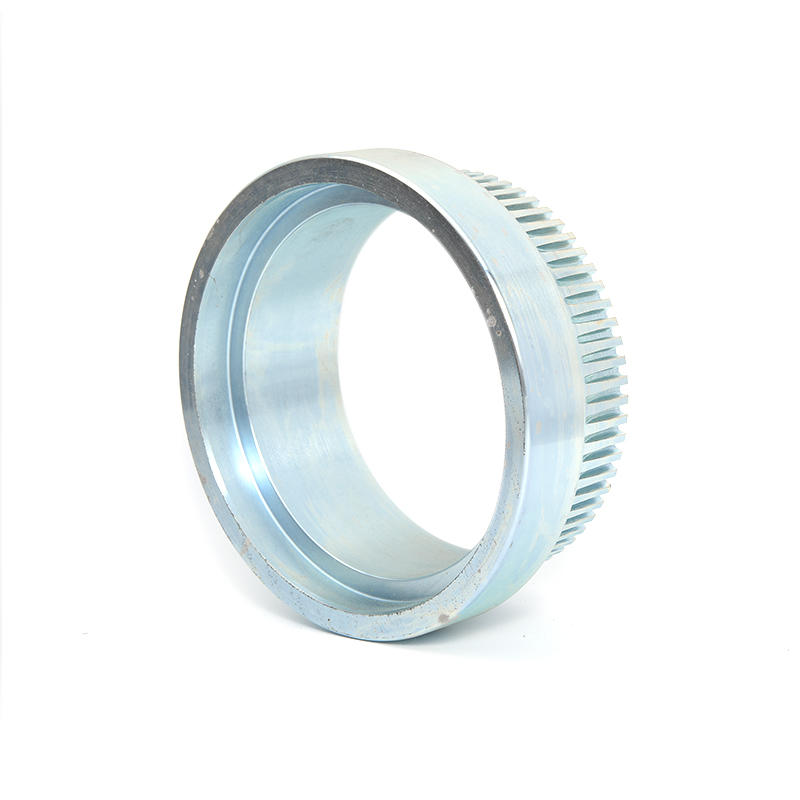

ABS Gear Ring Plane Gear is a vital component in the anti-lock braking system (ABS), and its design has a decisive impact on the performance of the ABS system. An in-depth discussion of its design principles and elements will not only help us understand the working principle of the ABS system, but also reveal how it affects the response speed and accuracy of the system.

First of all, from the perspective of response speed, the design of ABS Gear Ring Plane Gear requires comprehensive consideration of multiple aspects. Material selection is a key part of this. Materials with high strength and good wear resistance can ensure that gears maintain excellent performance under high-speed operation and frequent friction, and avoid performance degradation caused by material fatigue or wear. At the same time, reasonable structural design is also crucial. Optimizing the shape and layout of gears can reduce friction and resistance, thereby improving the response speed of the system. In addition, the size and fitting accuracy of the gears also need to be accurately calculated and adjusted to ensure that torque can be transmitted quickly and accurately during braking.

Secondly, in terms of accuracy, the design of the ABS Gear Ring Plane Gear also requires excellence. Tooth shape and pitch are important parameters in gear design, and they directly affect the stability and accuracy of gear transmission. Precise tooth profile design can ensure a stable transmission ratio during the meshing process of the gear and reduce braking instability or failure caused by transmission errors. A reasonable tooth pitch can ensure tighter and smoother meshing between gears, further improving braking accuracy.

In addition, the machining accuracy and assembly accuracy of the gears also have an important impact on the accuracy of the ABS system. The use of advanced processing technology and precision measuring equipment can ensure that the processing accuracy of the gears meets the design requirements. At the same time, strict assembly standards and quality control processes can also ensure the accuracy and stability of the gears during assembly. Together, these measures improve the manufacturing quality of the ABS Gear Ring Plane Gear, thereby improving the performance of the entire ABS system.

In addition to design and manufacturing considerations, we also need to pay attention to the maintenance and upkeep of ABS Gear Ring Plane Gear during use. Regular cleaning, lubrication and inspection of gears can ensure that they are always in optimal working condition and avoid performance degradation or failure caused by long-term use.

To sum up, the design of the ABS Gear Ring Plane Gear has a profound impact on the response speed and accuracy of the ABS system. By optimizing material selection, structural design, tooth pitch design, and improving processing and assembly accuracy, we can continuously improve the performance of ABS Gear Ring Plane Gear, thereby providing a more stable and accurate braking effect for the ABS system. This will provide drivers with a safer driving experience and reduce the risk of traffic accidents caused by braking problems.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com