Apr 25,2024

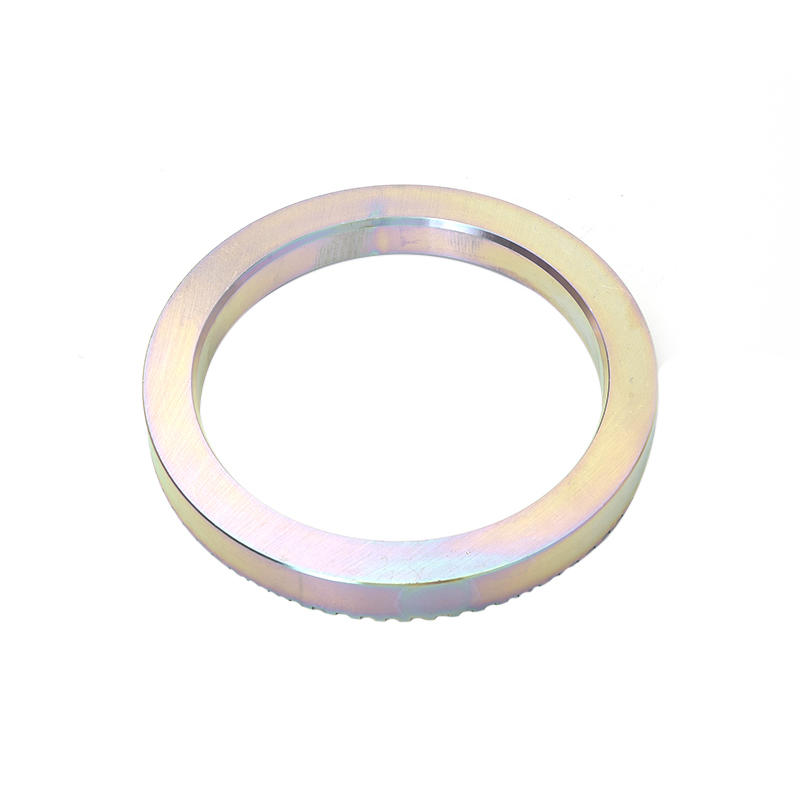

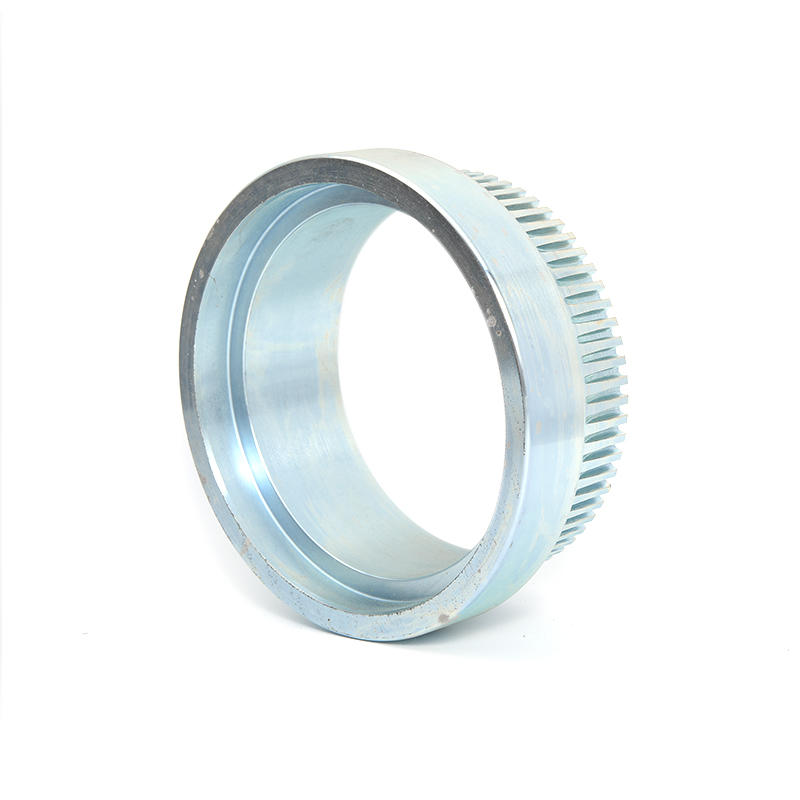

The axle sleeve, also known as a bearing cage or retainer, in an automobile ball cage plays a crucial role in maintaining the proper spacing and alignment of the balls within the bearing. The design of the axle sleeve can significantly impact the performance of the ball cage in several ways:

Ball Alignment and Spacing:

Design Influence: The shape and precision of the axle sleeve determine the alignment and spacing of the balls in the ball cage.

Performance Impact: Proper ball alignment and consistent spacing are critical for reducing friction and ensuring smooth operation. Any deviation in the design may lead to increased wear, noise, or reduced efficiency.

Durability and Material Selection:

Design Influence: The choice of materials for the axle sleeve and its design impact the overall durability and strength.

Performance Impact: Inadequate material selection or a weak design may result in premature failure, causing the balls to misalign or the axle sleeve to deform under load. This can lead to increased friction, heat generation, and potential bearing failure.

Heat Dissipation:

Design Influence: The design of the axle sleeve can affect the heat dissipation capability of the ball cage.

Performance Impact: Efficient heat dissipation is crucial for preventing overheating and thermal damage to the balls and cage. A well-designed axle sleeve facilitates proper ventilation and cooling, ensuring the bearing operates within its temperature limits.

Tolerance and Precision:

Design Influence: The manufacturing tolerance and precision in the design of the axle sleeve determine the overall quality of the ball cage assembly.

Performance Impact: Tight tolerances and precise machining contribute to reduced play, minimized vibration, and enhanced stability. Conversely, loose tolerances can result in increased play, noise, and decreased performance.

Lubrication Retention:

Design Influence: The design may include features that aid in lubrication retention.

Performance Impact: Adequate lubrication is essential for minimizing friction and wear. If the axle sleeve design does not facilitate proper lubrication retention, it may lead to dry spots, increased friction, and accelerated wear of the ball cage components.

Sealing and Contamination Prevention:

Design Influence: The axle sleeve design may incorporate sealing elements to prevent contaminants from entering the bearing.

Performance Impact: Effective seals help maintain a clean and contamination-free environment within the ball cage. Poor sealing can lead to increased wear, reduced performance, and potential damage to the balls and cage.

In summary, the design of the axle sleeve for an automobile ball cage is critical for ensuring proper ball alignment, durability, heat dissipation, precision, lubrication retention, and sealing. Engineers and manufacturers carefully consider these factors to optimize the performance, longevity, and reliability of the ball cage within automotive applications.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com