Jul 23,2024

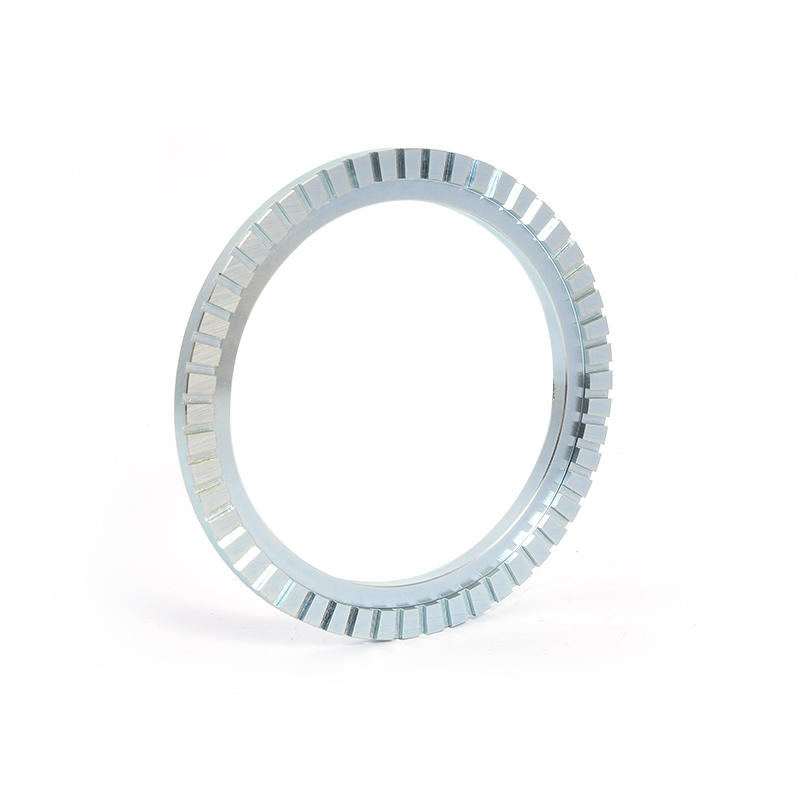

The heat treatment of the axle sleeve for the ball cage in an automobile has a profound impact on the strength and resilience of the ball cage components. Heat treatment, as a process that controls the physical and mechanical properties of metals, plays a crucial role in enhancing the performance of both the axle sleeve and the entire ball cage.

Firstly, heat treatment significantly improves the strength of the axle sleeve and, consequently, the ball cage components. By precisely controlling the heating and cooling rates, heat treatment can induce metallurgical changes within the material, such as grain refinement and phase transformations. These changes lead to a denser and more uniform microstructure, resulting in enhanced resistance to deformation and fracture. This increased strength ensures that the ball cage components exhibit greater stability and reliability when subjected to high loads and complex stress conditions.

Secondly, heat treatment also enhances the resilience of the ball cage components. Resilience, the ability of a material to recover its original shape and properties after being deformed or stressed, is crucial for the long-term reliability of the ball cage. Through heat treatment, the material of the axle sleeve becomes more ductile and tough, allowing it to better absorb and dissipate energy from impacts or vibrations. This improved resilience reduces the risk of fatigue failure or cracking in the ball cage components, ensuring their longer-term durability.

Furthermore, heat treatment can help to eliminate internal stresses and residual stresses that may have been introduced during the manufacturing process. These stresses can potentially lead to premature failure or deformation of the components. By relieving these stresses through heat treatment, the ball cage components are less likely to experience such issues, further enhancing their overall performance.

It is worth noting that to ensure the optimal effectiveness of heat treatment, advanced processing equipment and strict quality control measures are typically required. This includes precise control of key parameters such as heating temperature, soaking time, and cooling rate, as well as prompt responses to various situations that may arise during the treatment process. Through these measures, we can ensure the consistency and stability of the heat treatment process, thereby providing reliable performance guarantees for the ball cage components.

In conclusion, the heat treatment of the axle sleeve for the automobile ball cage significantly impacts the strength and resilience of the ball cage components. By optimizing the physical and mechanical properties of the material, heat treatment not only enhances the strength and resilience of the ball cage components but also eliminates potential manufacturing defects, providing robust support for the safe and reliable operation of automobiles. In practical applications, we should fully recognize the importance of heat treatment and take appropriate measures to ensure the optimization and stability of the treatment effect.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com