Nov 30,2024

Axle sleeve innovations are making a significant impact on the automotive industry, specifically in the areas of performance, fuel efficiency, and durability. Here's how these innovations are shaping the industry:

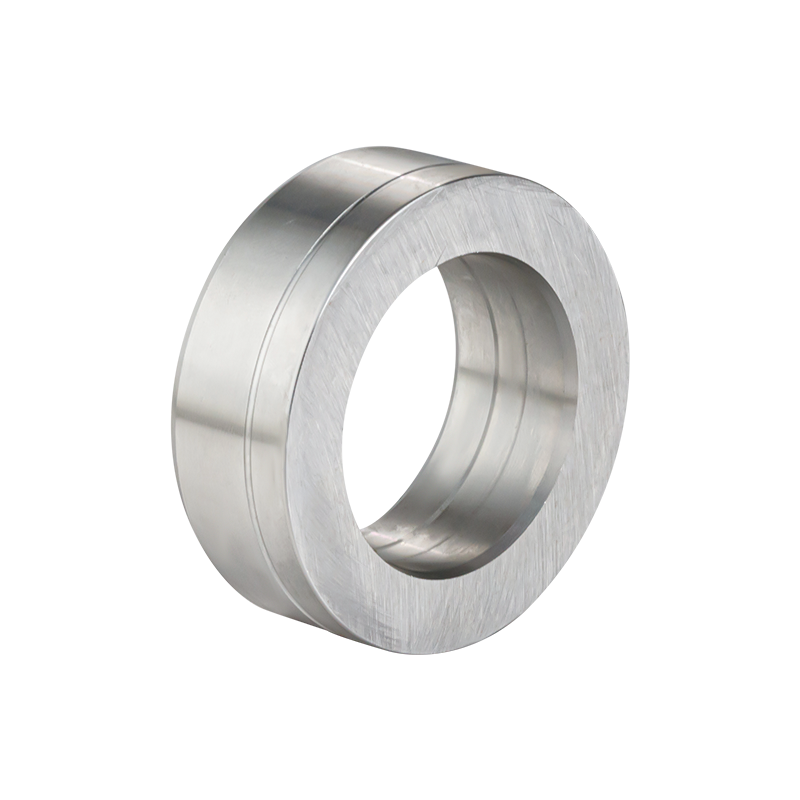

Performance Enhancement: Axle sleeves are a key component of the automotive drivetrain, transferring power from the engine to the wheels. Innovations in axle sleeve design and material have significantly improved performance, providing better torque capacity, improved strength, and increased fatigue resistance. For example, some modern axle sleeves are made from composite materials that offer a perfect combination of lightness, strength, and stiffness, resulting in improved acceleration and top speed for vehicles.

Fuel Efficiency: Axle sleeves play a crucial role in improving fuel efficiency. The friction losses in the drivetrain are one of the main causes of decreased fuel efficiency in vehicles. Innovative axle sleeve designs and coatings have significantly reduced friction losses, resulting in improved fuel efficiency. For instance, some sleeves are designed with low-friction coatings or are made from low-friction materials like PTFE, which reduce the amount of energy lost due to friction in the axle.

Durability: Axle sleeves are subjected to high stress and torque during operation, making durability a crucial factor for their performance. Innovations in material selection, heat treatment, and surface coatings have significantly improved the durability of axle sleeves. For example, special alloys and heat treatments can increase the fatigue resistance and hardness of the sleeve material, resulting in longer service life and reduced replacement costs.

Ease of Maintenance: Innovative axle sleeve designs can also simplify maintenance and reduce downtime. Some sleeves are designed to be easily replaceable, reducing the time and effort required for servicing. This not only saves time but also reduces the overall cost of ownership for vehicles.

Customization: With the advancement in additive manufacturing techniques like 3D printing, manufacturers can now produce axle sleeves with customized geometries and material properties. This allows for better fit and performance while meeting specific requirements of different vehicles and applications.

In conclusion, axle sleeve innovations are critical in shaping the automotive industry. They not only enhance performance, fuel efficiency, and durability but also simplify maintenance and allow for customization to meet specific needs. As the demand for fuel-efficient and high-performance vehicles continues to grow, axle sleeve innovations will play a pivotal role in meeting these demands while maintaining reliability and cost-efficiency.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com