Nov 30,2024

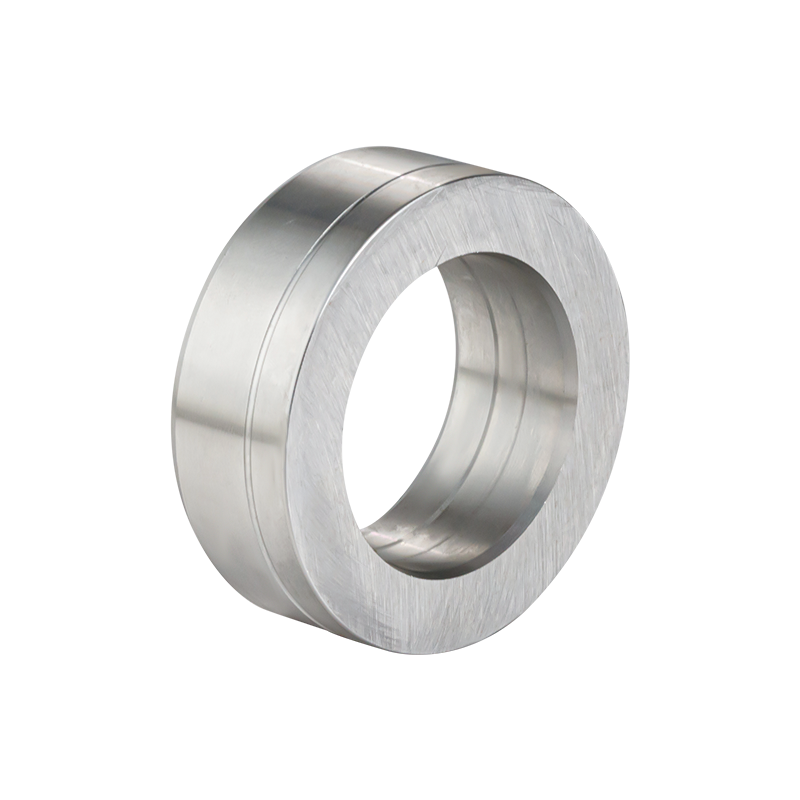

Selecting the right axle sleeve is a crucial decision for automotive manufacturers as it directly impacts the performance, safety, and durability of vehicles. Axle sleeves are components that protect and support axles, ensuring they operate smoothly and efficiently. Here are important factors to consider when choosing the right axle sleeve for automotive applications:

Material Selection:

The choice of material for axle sleeves is critical. Common materials include:

Steel: Traditional and widely used for its strength and durability.

Aluminum: Offers weight savings but may not be as robust as steel.

Composite Materials: Some modern vehicles use composite axle sleeves for weight reduction and corrosion resistance.

The material selected should match the vehicle's intended use, load capacity, and environmental conditions.

Size and Dimension:

Ensure the axle sleeve's size and dimension match the axle it will protect. Proper fitment is crucial to prevent wear and damage to both the axle and the sleeve.

Load Capacity:

Consider the maximum load capacity the axle sleeve needs to support. Different vehicles, from compact cars to heavy-duty trucks, have varying load requirements. Ensure the axle sleeve can handle the expected loads without deforming or failing.

Corrosion Resistance:

Axle sleeves are exposed to various environmental conditions, including road salt, moisture, and chemicals. Opt for materials and coatings that provide corrosion resistance to prolong the sleeve's lifespan.

Heat Resistance:

In high-performance and heavy-duty applications, axle sleeves may be subjected to extreme heat generated during braking or heavy loads. Choose materials that can withstand these elevated temperatures without deforming or weakening.

Sealing and Lubrication:

Some axle sleeves come equipped with built-in seals and lubrication channels. These features help reduce friction and wear on the axle, contributing to longer service life. Consider whether such features are necessary for your application.

Weight Considerations:

Weight is a crucial factor in automotive design, affecting fuel efficiency and handling. Aluminum or composite sleeves can offer weight savings, but ensure they still meet strength and durability requirements.

Regulatory Compliance:

Ensure that the chosen axle sleeve complies with relevant safety and regulatory standards in the region where the vehicles will be sold. Compliance is critical for vehicle safety and legal reasons.

Testing and Quality Assurance:

Partner with reliable suppliers who conduct rigorous quality control and testing on their axle sleeves. This includes dimensional checks, material quality tests, and performance evaluations to ensure the sleeves meet industry standards.

Cost and Supply Chain Considerations:

Balance the cost of axle sleeves with the desired quality and performance. Consider factors such as lead times, availability, and the reliability of the supplier.

Customization Options:

Depending on the specific needs of the vehicle, explore whether customization options, such as different materials, coatings, or designs, are available from the supplier.

Future-Proofing:

Consider how the choice of axle sleeve aligns with future automotive trends, such as electric vehicles (EVs) or autonomous vehicles. These emerging technologies may have unique axle sleeve requirements.

Choosing the right axle sleeve is a critical step in ensuring the safety, reliability, and performance of automotive vehicles. Manufacturers should carefully evaluate their specific requirements and work closely with trusted suppliers to make informed decisions regarding axle sleeve materials, design, and specifications.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com