Jul 23,2024

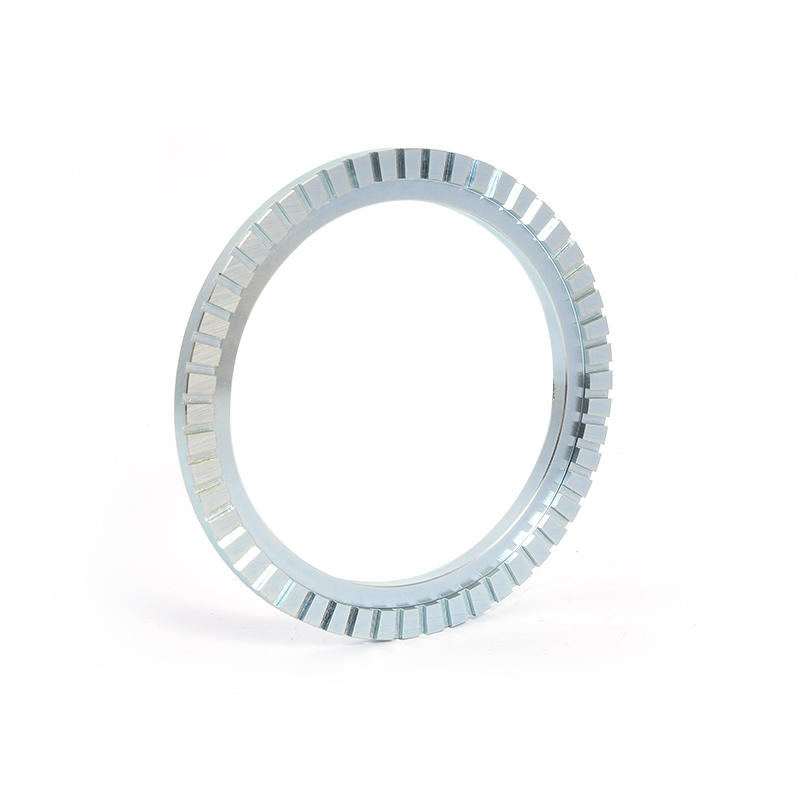

The utilization of lightweight materials in axle dleeve for sutomobile ball cage has emerged as a promising avenue for enhancing fuel efficiency in vehicles equipped with ball cage systems. This approach is not just based on conjecture, but rather on a combination of material science, engineering principles, and rigorous testing.

Firstly, the principle behind this lies in the fundamental relationship between weight and fuel consumption. Reducing the overall weight of a vehicle decreases the amount of energy required to propel it forward. Lightweight materials, such as advanced alloys, composites, or even certain types of plastics, can significantly cut down on the weight of axle sleeves without compromising their structural integrity.

In the context of ball cage systems, these lightweight materials can further optimize the system's performance. By reducing the inertia and frictional forces acting on the axle sleeves, these materials help the system operate more smoothly and efficiently. This decrease in energy loss translates into significant fuel savings, especially over long distances or under heavy loads.

Moreover, the selection of lightweight materials is not a random process. It involves a meticulous analysis of material properties, such as strength, stiffness, durability, and fatigue resistance. Engineers must ensure that the chosen materials not only reduce weight but also maintain or even enhance the safety and reliability of the axle sleeves.

Furthermore, the integration of these lightweight materials often requires innovative manufacturing techniques and precise assembly processes. This ensures that the axle sleeves are not only lighter but also more precisely fitted within the ball cage system, further reducing any potential for energy loss or inefficiencies.

To validate these claims, rigorous testing is conducted under various conditions. This includes both laboratory tests, simulating different driving scenarios and loads, as well as field tests, where the vehicles are put through their paces in real-world environments. The results of these tests are then analyzed to quantify the improvement in fuel efficiency and assess any potential trade-offs in terms of performance or durability.

In conclusion, the use of lightweight materials in axle sleeves is a well-researched and proven approach to enhancing fuel efficiency in vehicles with ball cage systems. It combines material science advancements, engineering principles, and rigorous testing to deliver tangible results.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com