Jul 23,2024

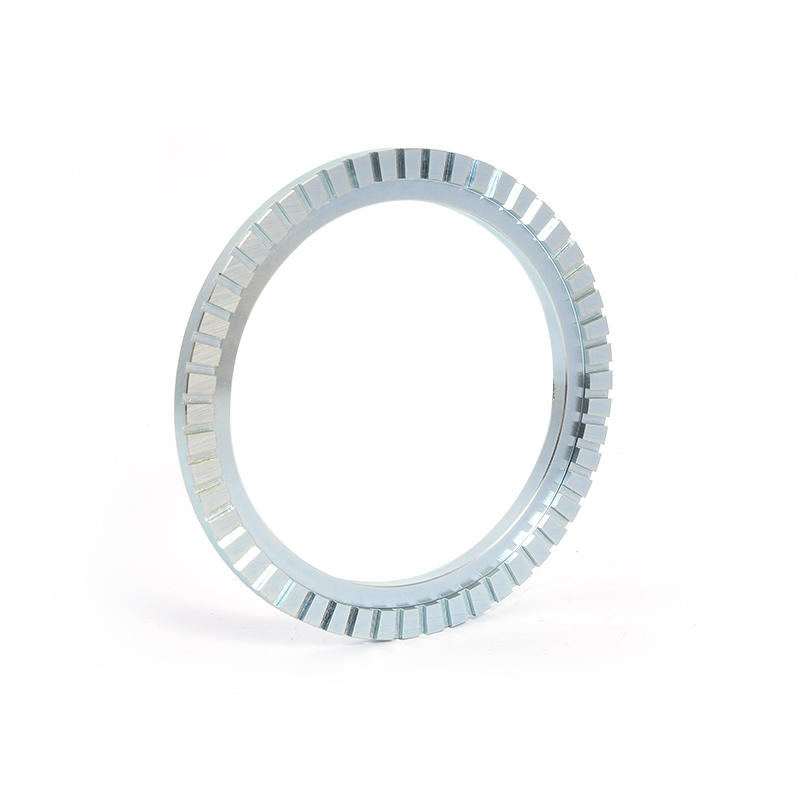

The axle sleeve for an automobile ball cage can enhance the efficiency of automotive ball cage systems in several ways:

Reduced Friction: A well-designed and precisely machined axle sleeve with a smooth surface finish reduces friction between the ball bearings and the raceway. This minimizes energy losses due to friction, allowing the bearings to rotate more freely and efficiently, thereby improving overall system efficiency.

Optimized Load Distribution: The axle sleeve helps distribute loads evenly across the ball bearings and the raceway. By providing a smooth and uniform surface for the bearings to roll against, the axle sleeve helps prevent localized stress concentrations and uneven wear, optimizing load distribution and improving the longevity of the ball cage system.

Enhanced Wear Resistance: A high-quality axle sleeve with a durable surface finish improves the wear resistance of the ball cage system. By minimizing surface roughness and imperfections, the axle sleeve reduces abrasive wear on the ball bearings and the raceway, extending the lifespan of the components and enhancing overall system efficiency.

Improved Sealing Performance: The axle sleeve can play a role in sealing effectiveness within the ball cage system. A properly machined and finished axle sleeve provides a better sealing surface for seals or shields, helping prevent contamination and moisture ingress into the bearing assembly. This improves the reliability and efficiency of the ball cage system by reducing the risk of premature failure due to environmental factors.

Noise and Vibration Reduction: A smooth and precisely machined axle sleeve contributes to noise and vibration reduction in the ball cage system. By minimizing surface irregularities and imperfections, the axle sleeve reduces noise generation and vibration levels during operation, resulting in a quieter and smoother-running automotive component.

Compatibility with Lubrication: The axle sleeve's surface finish affects its compatibility with lubricants used in the ball cage system. A smooth and properly finished axle sleeve promotes proper lubricant distribution and retention, ensuring effective lubrication of the ball bearings and the raceway. This helps reduce friction, dissipate heat, and protect against wear and corrosion, improving overall system efficiency and reliability.

Overall, the axle sleeve for an automobile ball cage can significantly enhance the efficiency of automotive ball cage systems by reducing friction, optimizing load distribution, enhancing wear resistance, improving sealing performance, reducing noise and vibration, and ensuring compatibility with lubrication. These factors collectively contribute to improved performance, longevity, and reliability of the ball cage system, ultimately enhancing the efficiency of automotive applications.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com