Jul 23,2024

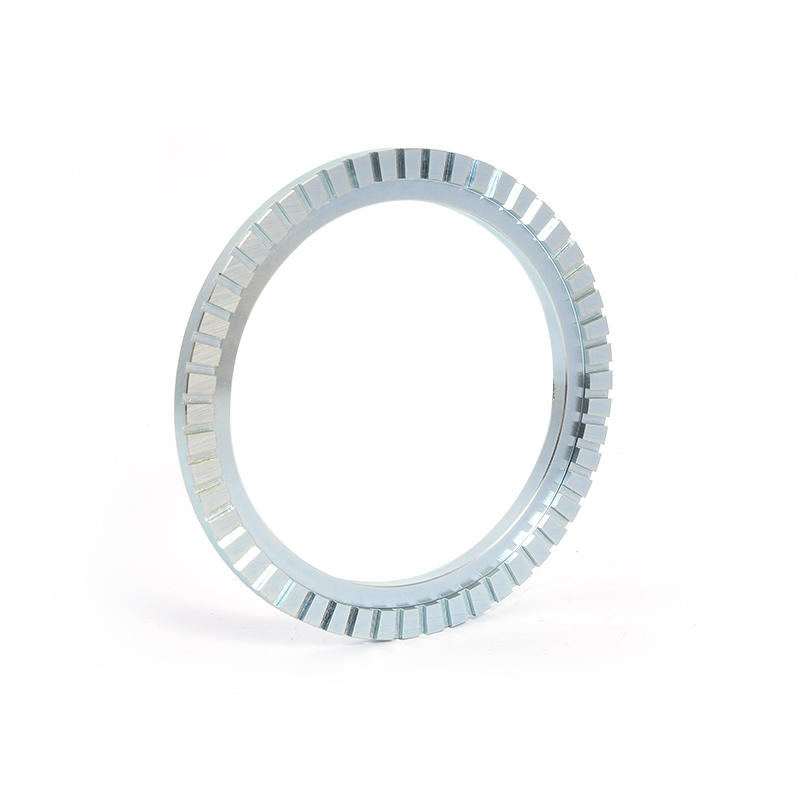

Advanced coating technologies can indeed improve the corrosion resistance of axle sleeves in ball cage applications. Corrosion resistance is a crucial factor in ensuring the durability and performance of axle sleeves, especially in environments where they are exposed to moisture, chemicals, or other corrosive agents.

Advanced coating technologies, such as physical vapor deposition (PVD), thermal spraying, and ceramic coatings, can provide a protective barrier on the surface of the axle sleeve for automobile ball cage. These coatings can enhance the corrosion resistance by creating a barrier that prevents corrosive substances from reaching the base material. They can also improve wear resistance, reduce friction, and enhance the overall performance of the axle sleeves.

The selection of the appropriate coating technology depends on the specific application requirements, including the type of corrosion, the operating environment, and the desired performance characteristics.

In addition to coating technologies, proper maintenance and inspection of the axle sleeves are also essential to ensure their long-term corrosion resistance and performance. Regular inspections can detect any signs of corrosion or wear, and prompt maintenance can prevent further damage or failures.

In conclusion, advanced coating technologies can significantly improve the corrosion resistance of axle sleeves in ball cage applications. However, it is important to choose the right coating technology based on the specific application requirements and to maintain the axle sleeves regularly to ensure optimal performance and durability.

English

English 中文简体

中文简体

+86-18352944301

+86-18352944301 +86-13003719355

+86-13003719355 info@xring-autoparts.com

info@xring-autoparts.com